1. Introduction

Agentic AI, a cutting-edge advancement in artificial intelligence, empowers systems to autonomously reason, plan, and execute tasks with minimal human intervention. In the manufacturing sector, this technology is poised to redefine operations by boosting efficiency, slashing costs, and elevating product quality.

According to Gartner (2024), agentic AI is a pivotal business trend for 2025, with projections indicating that 33% of enterprise software applications will incorporate it by 2028. This blog post delves into how agentic AI is transforming manufacturing, explores its key applications, addresses challenges, and outlines a roadmap for adoption.

>> Explore here to read more about AI use cases in manufacturing industry

2. The Current AI Landscape in Manufacturing

The manufacturing industry has embraced AI for tasks like predictive maintenance, quality control, and supply chain management. However, agentic AI takes this a step further by enabling systems to make decisions independently, ushering in an era of smart factories. These systems can monitor equipment in real-time, predict maintenance needs, and initiate actions autonomously. The World Economic Forum report (2025) highlights that AI agents are revolutionizing both direct and indirect manufacturing functions, enhancing software systems and physical automation. With 89% of companies planning to implement AI in their production networks and 78% of manufacturers integrating autonomous AI into their strategies, the industry is on the cusp of a significant transformation.

3. Key Applications & Use Cases

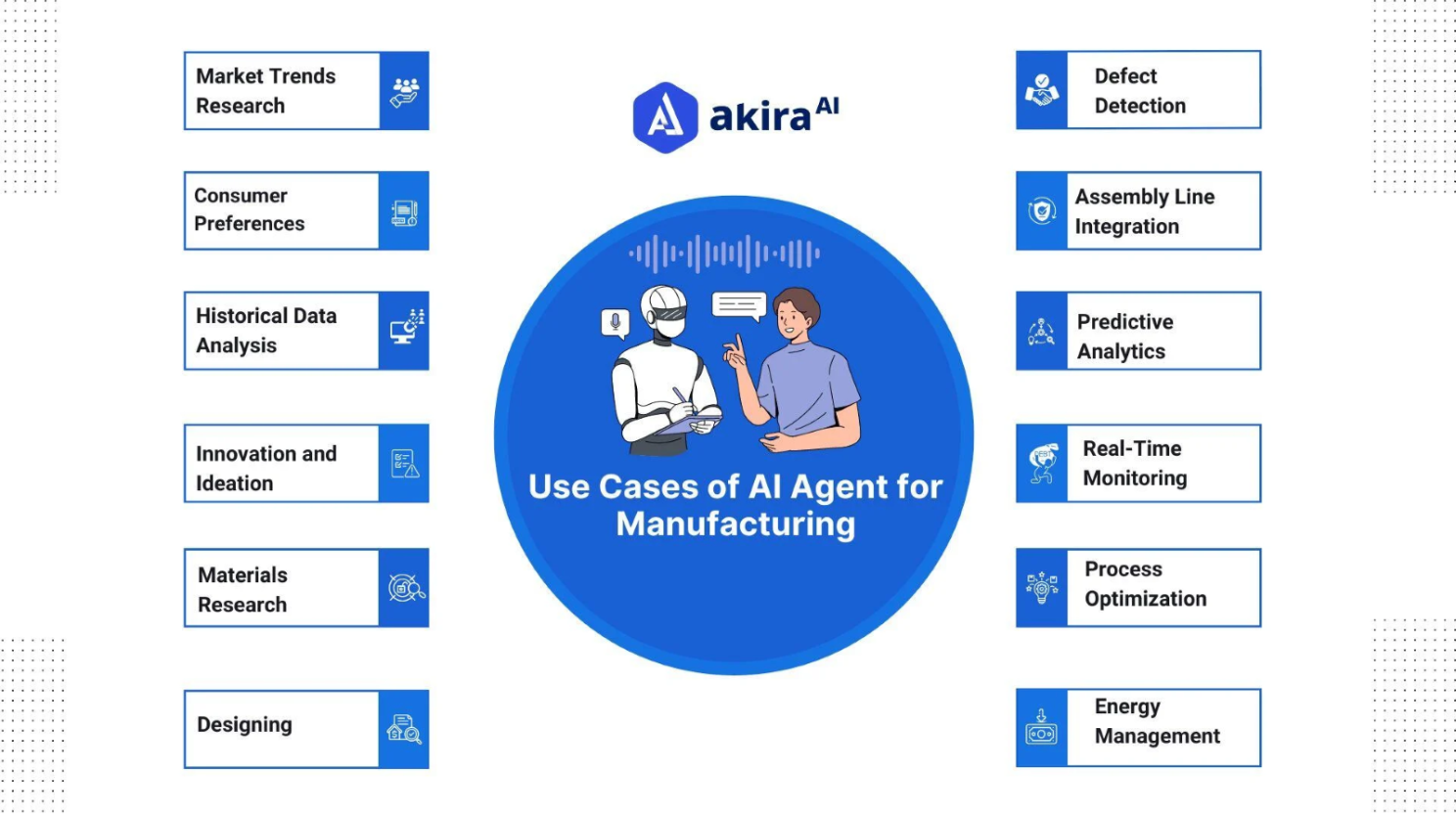

Agentic AI is driving innovation across various manufacturing processes. Below are key applications, supported by real-world case studies.

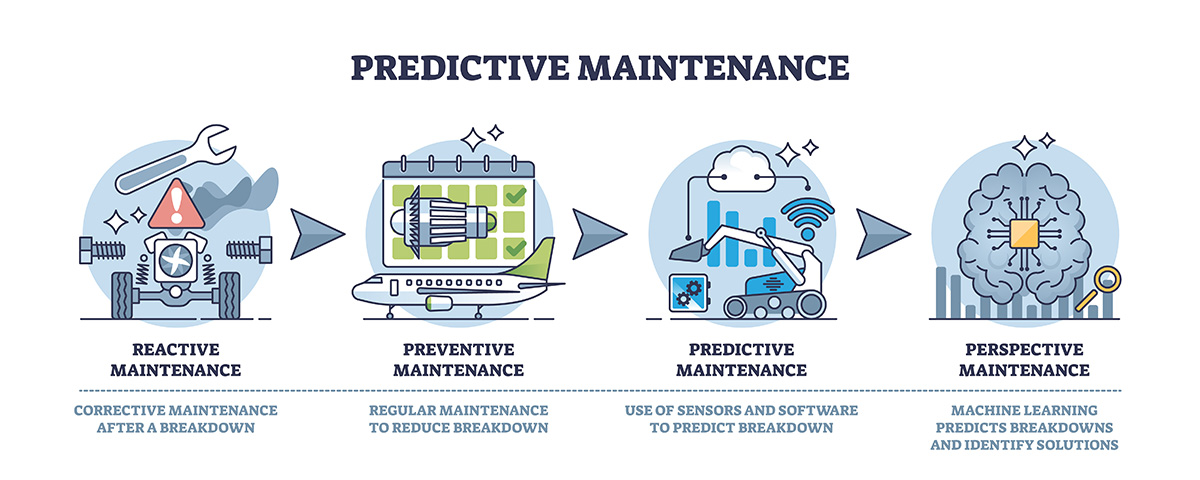

3.1. Predictive Maintenance & Quality Control

Agentic AI leverages real-time sensor data, historical records, and machine learning to predict equipment failures before they occur, enabling proactive maintenance scheduling. It also enhances quality control by using computer vision and predictive analytics to detect microscopic defects, ensuring consistent product quality. For instance, AI systems can analyze vibration, temperature, and performance data to forecast maintenance needs with up to 95% accuracy, reducing quality issues by 60%. This minimizes downtime, reduces waste, and maintains high standards.

Case study: Siemens, a global industrial manufacturing leader, tackled costly downtime and maintenance inefficiencies by integrating agentic AI into its operations. Through its Senseye Predictive Maintenance platform and Digital Twins technology, Siemens uses generative AI and machine learning to predict equipment failures, streamline maintenance via a conversational interface, and simulate machine behavior with virtual replicas. These innovations enable proactive maintenance, reducing unexpected interruptions, cutting costs, boosting productivity, and preserving expert knowledge for future use — all while ensuring data privacy through secure private cloud processing.

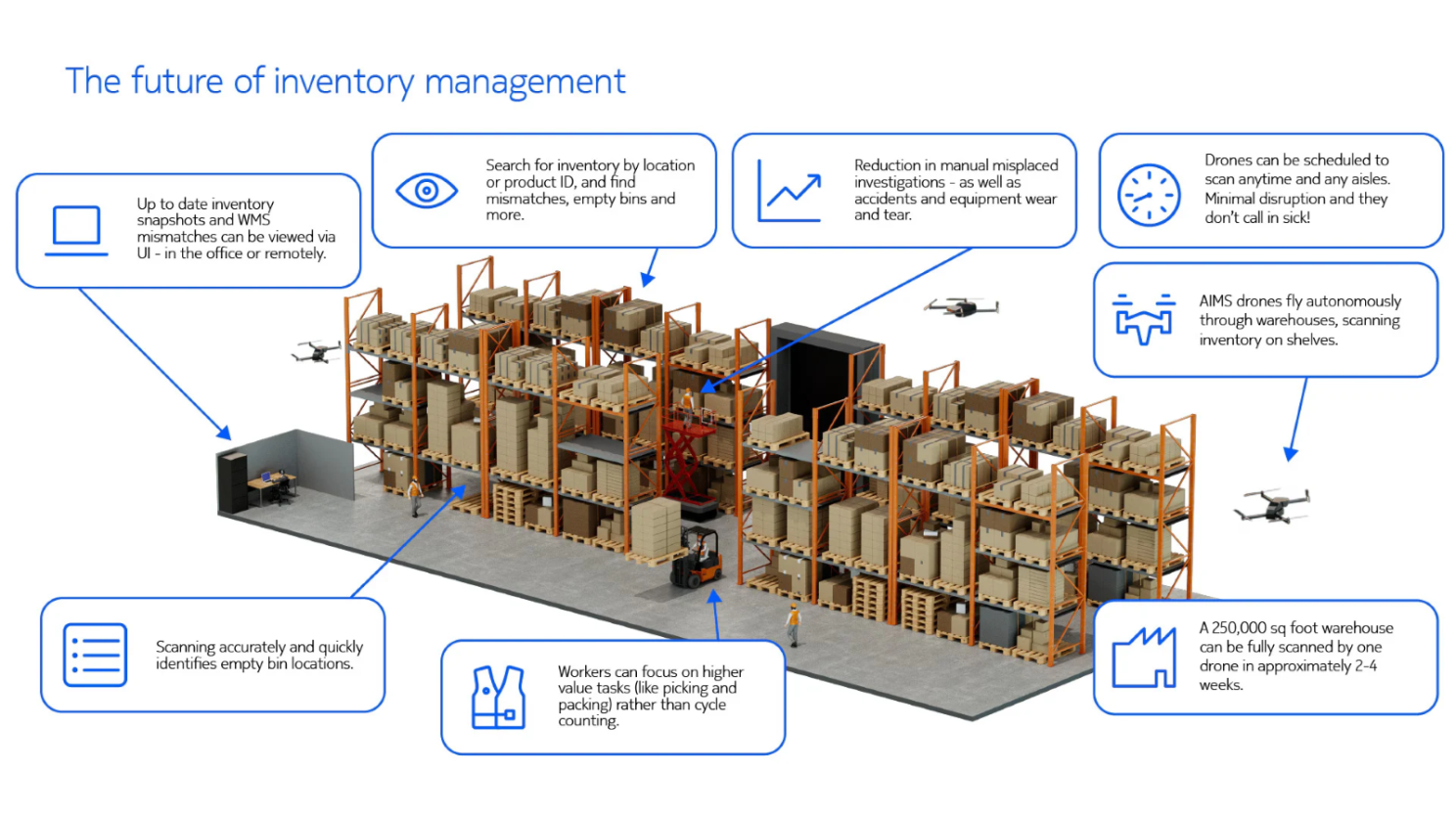

3.2. Autonomous Inventory Management

Agentic AI autonomously tracks material levels, reorders supplies, and optimizes delivery schedules by analyzing real-time sales data, historical trends, and market conditions. It uses predictive algorithms, such as time-series forecasting and decision trees, to ensure optimal inventory levels, reducing stockouts and overstocking. This can cut inventory costs by up to 30%, ensuring timely availability of materials while minimizing waste.

Case study: Walmart, the world’s largest retailer, uses agentic AI to streamline inventory management across its vast network. By integrating predictive algorithms and platforms like Blue Yonder, Walmart leverages POS data to forecast demand, automate replenishment, and optimize supply chains. During peak seasons, AI pre-positions high-demand items at regional warehouses, reducing stockouts and ensuring product availability. This approach lowers inventory holding costs, accelerates fulfillment, and boosts customer satisfaction through smarter, faster inventory decisions.

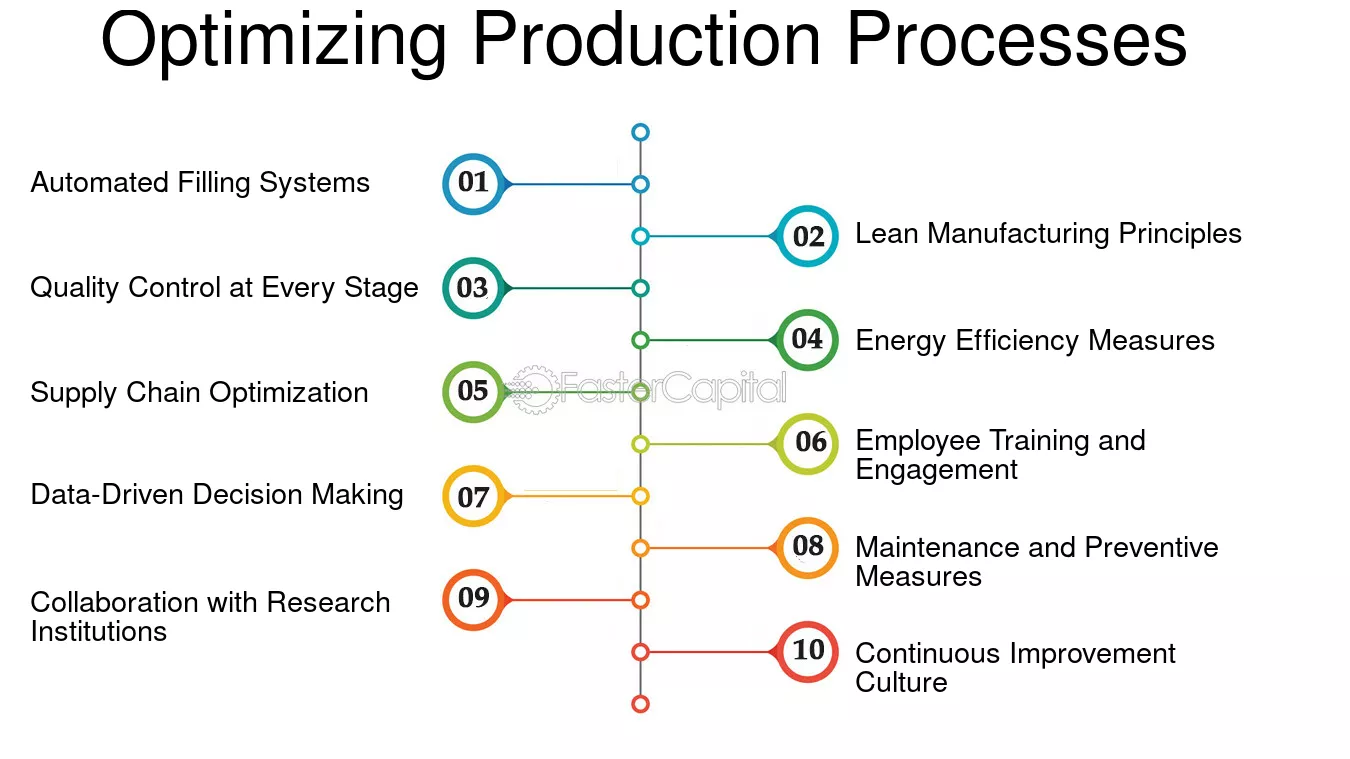

3.3. Self-Optimizing Production Lines

Agentic AI autonomously monitors production lines, adjusts schedules, and optimizes resource allocation in real-time. It uses sensors, IoT devices, and machine learning to detect inefficiencies, predict equipment failures, and adapt to changing demands. This can boost productivity by up to 15% and reduce logistics costs by 15%, ensuring continuous process improvement and flexibility.

Case study: Siemens enhances production efficiency by deploying agentic AI to create self-optimizing manufacturing lines. Using machine learning, predictive analytics, and AI agents integrated with tools like Senseye and Siemens Xcelerator, the system gathers real-time data from IoT sensors to predict failures and autonomously adjust schedules and resources. At its German electronics factory, this approach cut faults from 500 to 12 per million actions. The result: reduced downtime, improved quality, increased productivity, and greater adaptability to shifting market demands.

4. Challenges & Risks

While agentic AI offers immense potential, its adoption in manufacturing faces several hurdles:

- Integration with Legacy Systems: Many manufacturers rely on outdated infrastructure, making integration costly and complex. Siemens and Boeing addressed this through partnerships and IT upgrades.

- Data Quality and Security: Poor data quality can lead to inaccurate decisions, and sensitive manufacturing data requires robust security. Establishing data governance frameworks, as Toyota did, is critical.

- Skilled Workforce: Implementing agentic AI requires specialized skills. Training programs, like those at Georgia-Pacific, help bridge this gap.

- Regulatory Compliance: Compliance with data privacy and safety regulations is essential. Boeing strengthened cybersecurity to meet these requirements.

- Trust and Acceptance: Employee resistance due to job displacement fears can hinder adoption. Comprehensive training and clear communication, as seen in Toyota’s approach, foster acceptance.

To mitigate these risks, manufacturers can adopt strategies from successful case studies, such as partnering with tech firms, investing in training, and ensuring robust data management.

5. Roadmap for Adoption

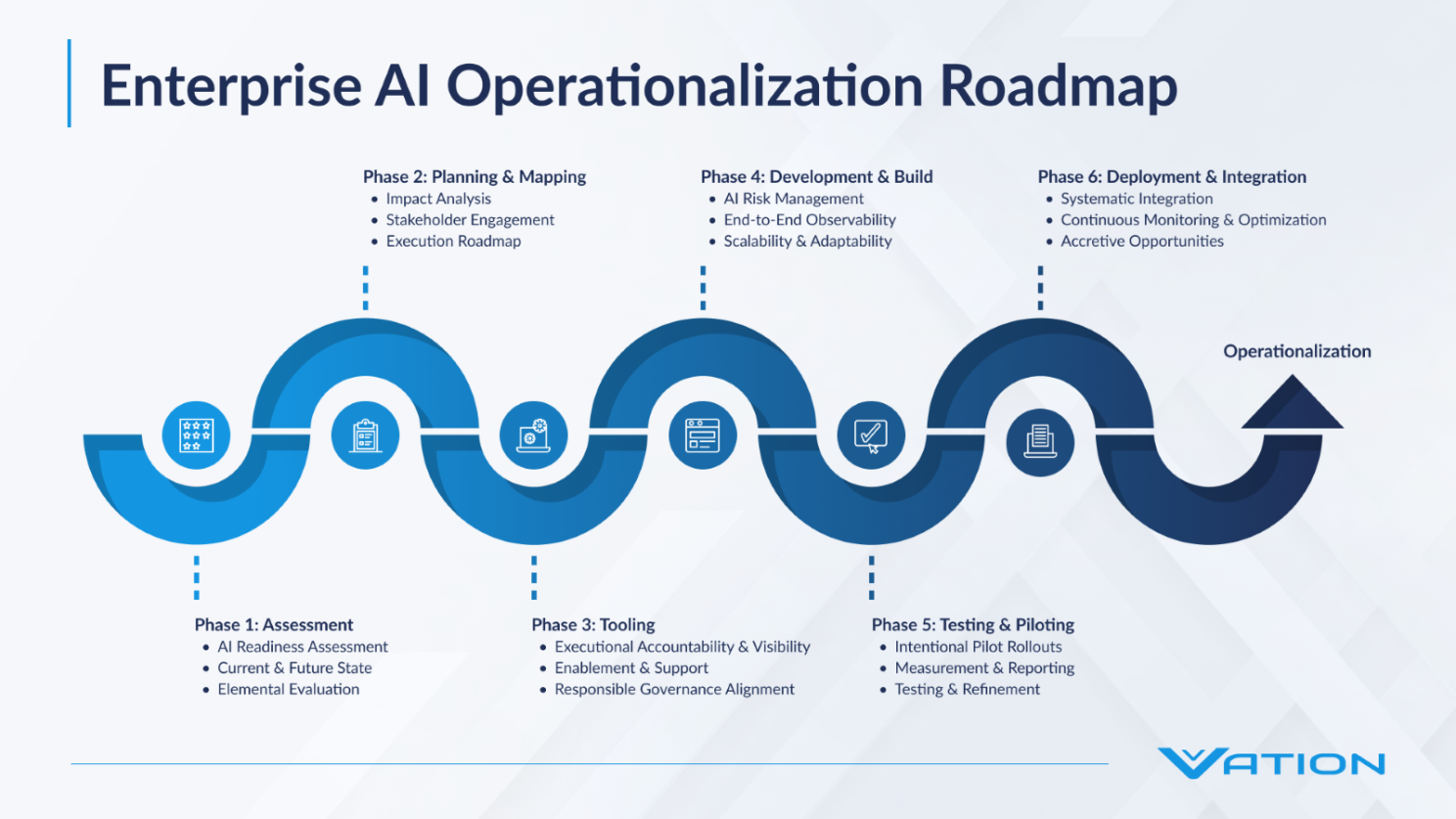

To successfully integrate agentic AI, manufacturers can follow a structured approach:

- Assessment and Planning: Evaluate AI readiness using tools like INCIT’s Artificial Intelligence Readiness Index (AIRI) INCIT. Identify high-impact areas like predictive maintenance or supply chain optimization.

- Pilot Projects: Launch small-scale pilots to test AI solutions, gathering data and feedback to refine implementations.

- Scalable Implementation: Expand successful pilots across operations, integrating AI with existing systems and ensuring compliance.

- Continuous Improvement: Monitor AI performance and adapt systems based on new data to ensure long-term effectiveness.

This roadmap ensures a structured, low-risk adoption process, maximizing the benefits of agentic AI.

6. Conclusion & Call to Action

Agentic AI is transforming manufacturing by enabling autonomous, efficient, and intelligent operations. With the potential to reduce maintenance costs by up to 30%, unplanned downtime by 45%, and boost supply chain efficiency by 25%, it is a critical tool for staying competitive. As the industry evolves, staying informed about agentic AI developments is essential. Subscribe to our newsletter for regular updates and insights to help your organization harness this transformative technology.