AI-powered production planning and scheduling has become one of the most decisive levers for manufacturers seeking operational resilience, cost efficiency, and competitive differentiation. This article examines how AI-powered production planning and scheduling fundamentally reshapes manufacturing operations. It explores the underlying limitations of conventional approaches, explains how AI models work in real production environments, and analyzes the tangible business outcomes manufacturers can expect when AI is deployed responsibly and at scale.

>> Click here to explore how to transfer from PoCs to production in the companies!

1. AI-Powered Production Transform Your Business

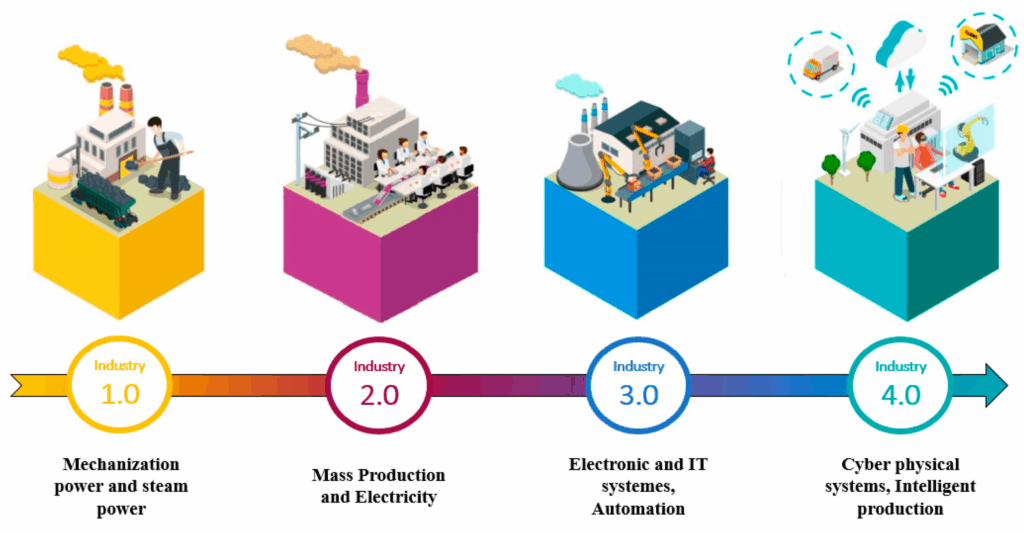

As global supply chains grow more volatile, product lifecycles shorten, and customer expectations move toward mass customization, traditional rule-based or spreadsheet-driven planning systems are no longer sufficient. What was once a back-office optimization task has evolved into a strategic capability that directly influences service levels, margins, and long-term scalability.

To thrive in this dynamic environment, businesses must leverage advanced analytics and artificial intelligence to enable real-time decision-making and predictive insights. Emphasizing agility and responsiveness in manufacturing operations will not only enhance competitive differentiation but also foster stronger customer relationships in an increasingly consumer-driven marketplace.

2. The Structural Limits of Traditional Production Planning

Conventional production planning and scheduling relies heavily on static assumptions. Lead times are often fixed, capacity is treated as stable, and demand forecasts are generated in isolation from execution realities. While these approaches may function adequately in predictable environments, they struggle under modern manufacturing conditions characterized by variability and interdependence.

These structural weaknesses in legacy planning systems contribute to a significant disconnect between strategic intent and operational resilience, leading to inefficiencies that can hinder overall productivity. Static optimization makes it challenging to adapt to unplanned disruptions or fluctuating demand, while the limited handling of complex constraints can result in suboptimal resource allocation. Additionally, the reliance on manual intervention for problem-solving detracts from long-term strategic improvements, and siloed decision-making prevents a holistic view of manufacturing operations. Consequently, organizations face the repercussions of missed delivery commitments, excess inventory, and underutilized assets, ultimately jeopardizing their competitive differentiation position in a rapidly evolving market.

3. What Makes AI-Powered Planning Fundamentally Different

AI-powered production planning departs from deterministic logic and instead relies on probabilistic, data-driven decision-making. Rather than asking “What is the best schedule given fixed assumptions?”, AI-powered production systems continuously ask “What is the best decision right now, given uncertainty and trade-offs?”

This adaptability allows AI-powered planning systems to proactively adjust to variations in demand and supply chain disruptions, ensuring that organizations can maintain efficient manufacturing operations. By harnessing machine learning for precise forecasting and employing optimization algorithms to navigate complex scheduling challenges, these systems enhance decision-making in real time. Reinforcement learning further contributes by allowing continuous improvement based on past experiences and outcomes, while simulation and digital twins enable organizations to explore various scenarios and mitigate risks before implementation. Ultimately, this approach transforms traditional planning from a static framework into a dynamic capability that thrives amidst uncertainty and rapid change.

4. Core Capabilities of AI-Powered Production Planning

4.1 Demand-Aware and Constraint-Driven Scheduling

AI models ingest historical sales, real-time orders, seasonality signals, and external data to generate demand forecasts that are both granular and continuously updated. These forecasts are then directly embedded into scheduling logic, ensuring that production priorities reflect actual market conditions rather than outdated plans.

By explicitly incorporating these constraints, AI schedulers create comprehensive and realistic production plans that align closely with operational resiliance, capabilities and strategic goals. This nuanced approach ensures that vital factors like machine downtime, workforce qualifications, supply chain reliability, and sustainability objectives are systematically accounted for, leading to more effective resource utilization. As a result, organizations can achieve not just feasible schedules, but also economically optimal ones that enhance profitability and support long-term sustainability initiatives. Such intelligent scheduling empowers businesses to respond effectively to market demands while maintaining efficiency and reducing waste in their operations.

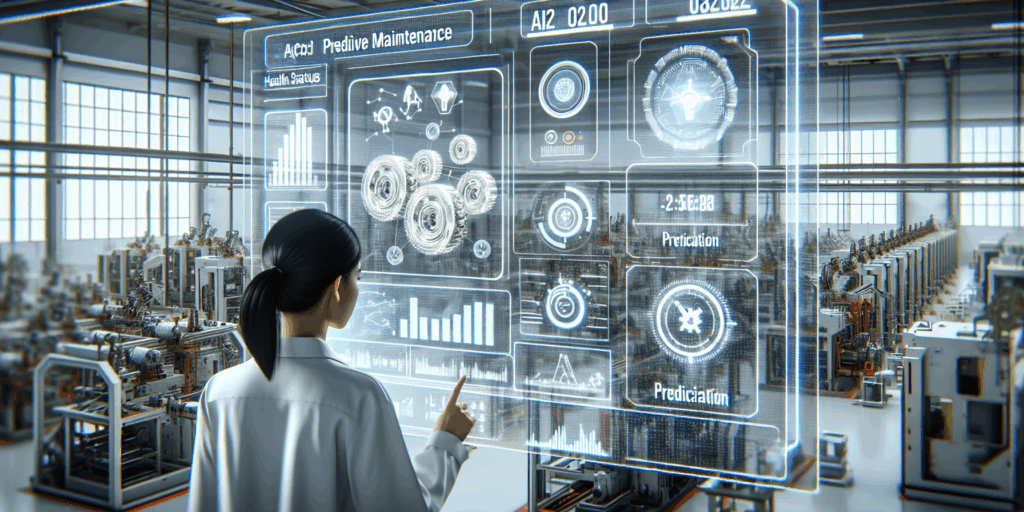

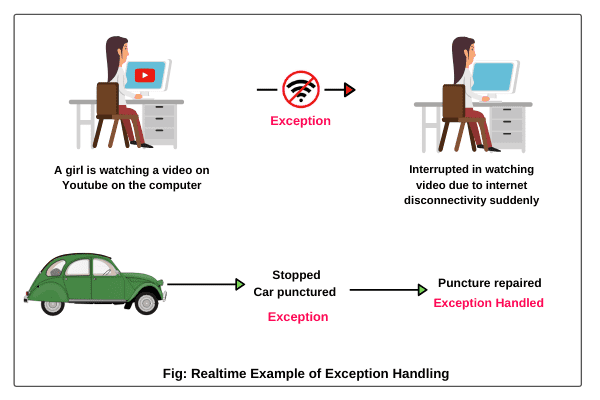

4.2 Real-Time Replanning and Exception Handling

One of the most transformative aspects of AI-powered scheduling is its ability to replan dynamically. When a machine fails, a shipment is delayed, or a rush order arrives, the system can generate a revised schedule in minutes rather than hours or days. This capability reduces the organizational dependence on individual planners’ experience. Decisions become consistent, explainable, and scalable across plants and regions.

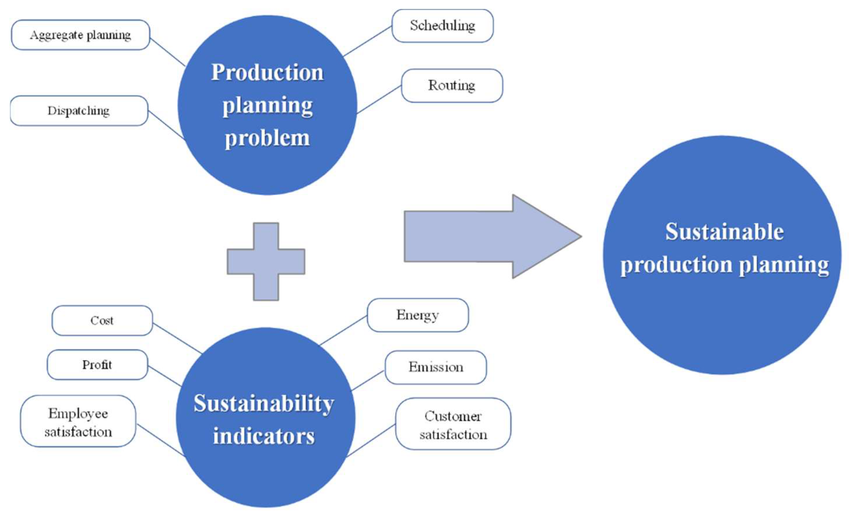

4.3 Multi-Objective Optimization

Production planning rarely has a single objective. Manufacturers must balance cost, service level, throughput, inventory, and sustainability. AI-powered production excels at navigating these trade-offs by optimizing across multiple objectives simultaneously. For example, an AI system can evaluate whether meeting a rush order is worth the overtime cost, energy premium, and downstream disruption, and then present decision-makers with ranked alternatives rather than a single opaque recommendation.

4.4 Learning from Execution Outcomes

AI-powered systems close the loop between planning and execution. Actual production data is continuously fed back into the models, allowing them to learn from deviations between plan and reality. As the AI scheduler continuously analyzes data and learns from historical patterns, it refines its understanding of cycle times and potential disruptions, leading to progressively more accurate forecasts.

This dynamic learning process fosters a stronger alignment between planning assumptions and actual shop-floor behavior, minimizing discrepancies and enhancing operational effectiveness. Consequently, rather than relying on static rules that require manual adjustments, the system evolves organically, adapting to changes and providing insights that drive better decision-making. Over time, organizations benefit from increased efficiency, reduced lead times, and a more responsive supply chain, ultimately enhancing their competitive edge in a volatile market.

5. Business Impact Across Manufacturing Functions

This reduction in excess inventory not only frees up working capital, allowing organizations to allocate resources more effectively, but also minimizes holding cost efficiency associated with surplus stock. As a result, manufacturers can maintain optimal inventory levels without sacrificing customer satisfaction, leading to a more agile and efficient supply chain. Moreover, by enhancing visibility across operations and fostering closer collaboration with suppliers, companies can further streamline their processes, reduce waste, and respond swiftly to market demands. Ultimately, the integration of AI in planning not only drives operational resilience but also fosters a culture of continuous improvement and responsiveness, benefiting both manufacturers and their customers.

This shift allows planners to engage in more value-added activities, enhancing the overall quality of decision-making. With AI-powered production providing data-driven insights and scenario analysis, planners can prioritize strategic initiatives that drive operational resilience efficiency and innovation. As they focus on refining processes and aligning resources with business objectives, organizations benefit from not only improved asset utilization but also a more informed and proactive planning approach. This transformation leads to a more resilient and adaptive supply chain, where human expertise and AI collaboration create a synergistic effect that enhances overall performance and responsiveness to changing market conditions.

6. Organizational and Technical Prerequisites

Successful adoption of AI-powered planning hinges on a foundation built on data readiness, robust governance, and incremental deployment. High-quality data from various systems such as ERP, MES, SCADA, and supply chain management is essential for AI-powered production systems to function effectively. Ensuring data consistency, timestamp accuracy, and seamless integration is far more critical than merely accumulating vast amounts of data.

Additionally, a human-in-the-loop governance framework is vital, as AI should complement human decision-making rather than replace it. Effective systems provide clear override mechanisms and explainable recommendations, allowing planners to retain control and ensure that decisions align with organizational objectives. Moreover, implementing AI in a focused, incremental manner, starting with a specific use case such as a single plant or product family that enables organizations to validate models and build trust before scaling them across operations.

Despite the promise of AI, several misconceptions can hinder effective implementation. A prevalent belief is that AI will automatically rectify poor processes; however, the reality is that AI systems amplify existing strengths and weaknesses. If foundational data is flawed or constraints are inaccurately defined, the outcomes will inevitably fall short of expectations. Additionally, there is a risk of over-automation, where reliance on opaque, black-box decisions erodes trust and poses compliance challenges, especially in regulated sectors. Therefore, a balanced approach to AI integration is essential, one that prioritizes transparency, aligns with existing processes, and fosters collaboration between human planners and AI systems to achieve optimal results.

Conclusion

AI-powered production planning and scheduling represents a decisive shift from static optimization to adaptive intelligence. By embedding learning, simulation, and multi-objective reasoning into the heart of manufacturing operations, AI enables decisions that are faster, smarter, and more aligned with real-world conditions. The journey requires discipline, data maturity, and thoughtful governance. However, for manufacturers willing to embrace this transformation, the reward is not just operational efficiency, but a fundamentally more resilient and competitive production system.