AI-powered supply chain optimisation is transforming how businesses manage their logistics, procurement, and inventory. Traditional methods of managing logistics, procurement, and inventory are often inadequate, unable to respond quickly enough to the fluctuations in demand or disruptions caused by external factors. This is where AI-powered supply chain optimisation comes in. By integrating artificial intelligence technologies such as machine learning and predictive analytics, companies can streamline operations, reduce costs, and enhance decision-making across every part of the supply chain.

>> Read more: Top 6 Top Latest Practical AI in Manufacturing Use Cases

In this blog post, we will explore how AI can optimise for supply chain efficiency across key areas such as inventory management, route optimisation, warehouse automation, supplier relationship management, and real-time monitoring.

1. The Role of AI-Powered Supply Chain Optimisation

AI-powered supply chain optimisation refers to the use of artificial intelligence technologies, including machine learning, deep learning, and predictive analytics, to enhance decision-making and improve operational efficiency across the supply chain. AI systems can analyse vast amounts of data in real-time, providing insights into everything from stock levels and production schedules to route planning and customer demand forecasts.

Key benefits include:

- Automation: Tasks that once required manual oversight can now be automated, freeing up human resources for more strategic activities.

- Predictive insights: AI can anticipate demand fluctuations, allowing businesses to adjust inventory and production accordingly.

- Real-time decision-making: AI systems can provide immediate data-driven insights to optimise decisions in real-time.

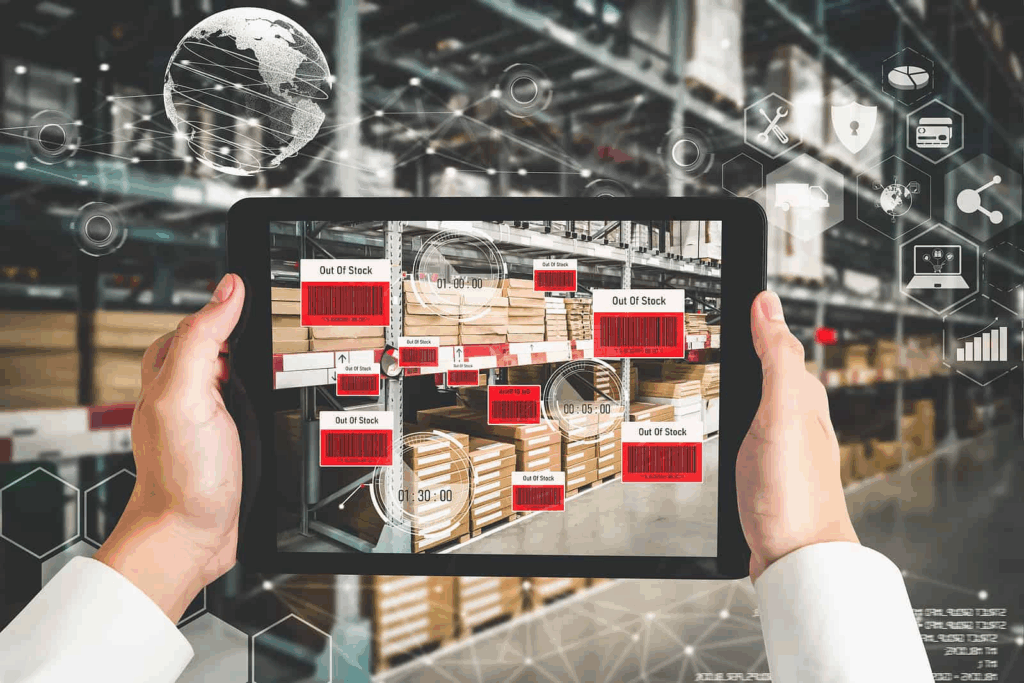

2. Inventory Management: Streamlining Stock Control with AI

One of the biggest challenges in supply chain management is ensuring that the right products are available at the right time. AI-powered inventory management systems can predict future demand by analysing historical data, seasonal trends, and external factors like market conditions or consumer behavior (Takyar, 2023).

- Demand Forecasting: AI models can process historical sales data, consumer trends, and external data to predict demand more accurately. This helps businesses avoid stockouts or excess inventory, optimising cash flow and reducing storage costs.

- Optimisation Algorithms: AI can optimise inventory levels across multiple warehouses, ensuring that stock is distributed in the most efficient way possible, based on predicted demand patterns.

- Automated Replenishment: AI can trigger automatic reorder points, reducing the need for manual intervention and ensuring stock levels remain optimal at all times.

By implementing AI-powered inventory management solutions, companies can improve inventory turnover, reduce wastage, and ensure a more seamless supply chain.

3. Route Optimisation: Saving Time and Reducing Costs

Transportation costs are a significant portion of any supply chain budget. Route optimisation powered by AI enables companies to reduce fuel costs, delivery times, and improve driver safety. By leveraging real-time data, AI can calculate the most efficient routes, accounting for factors such as traffic, weather conditions, and road closures.

- Dynamic Routing: AI systems can adjust routes in real-time based on changing conditions, ensuring timely deliveries and preventing delays.

- Cost Reduction: By optimising delivery routes, businesses can reduce fuel consumption and vehicle wear-and-tear, leading to significant cost savings.

- Improved Delivery Times: Faster and more reliable deliveries not only reduce operational costs but also increase customer satisfaction.

AI-powered route optimisation not only helps reduce operational costs but also enhances supply chain responsiveness, allowing businesses to deliver products more efficiently.

4. Warehouse Automation: The Future of Storage and Distribution

Warehouse management is a critical component of supply chain optimisation, as it directly impacts delivery speed, inventory control, and cost management. AI can automate several tasks within the warehouse, from sorting and storing goods to packing and shipping.

- Automated Picking Systems: AI-powered robots and drones are transforming warehouse operations by automating picking and packing tasks. These machines can locate products, pick them, and pack them more quickly and accurately than human workers.

- Intelligent Storage Systems: AI can optimise the arrangement of goods in a warehouse, determining the most efficient storage locations for each item based on factors like demand frequency and size. This reduces retrieval time and enhances overall operational efficiency.

- Predictive Maintenance: AI can predict when warehouse equipment is likely to fail and schedule preventative maintenance, reducing downtime and keeping operations running smoothly.

Warehouse automation powered by AI can significantly improve processing times, reduce human errors, and enhance inventory control.

5. Shipping Optimisation: Reducing Costs and Improving Delivery Efficiency

Shipping is another area where AI can have a significant impact. AI-powered shipping optimisation systems analyse historical shipping data, customer preferences, and external factors to determine the most cost-effective shipping methods.

- Dynamic Shipping Rates: AI can dynamically calculate shipping costs based on factors like package size, delivery location, and time of year, ensuring that businesses can offer competitive shipping rates to customers.

- Optimised Delivery Networks: By optimising shipping routes and consolidating shipments, AI can reduce the number of trips and the distance travelled, cutting down on transportation costs.

- Last-Mile Optimisation: AI can help optimise last-mile deliveries by predicting the most efficient delivery windows, reducing delays and improving customer satisfaction.

Shipping optimisation through AI not only reduces costs but also ensures that products are delivered quickly and efficiently to customers.

6. Real-Time Supply Chain Monitoring: Proactive Problem-Solving

The ability to monitor and manage the entire supply chain in real-time is a game-changer for businesses. AI-powered systems provide end-to-end visibility, allowing managers to track shipments, monitor inventory levels, and even predict potential issues before they arise.

- End-to-End Visibility: AI integrates data from various sources to provide a comprehensive view of the entire supply chain. This helps businesses identify bottlenecks, monitor supplier performance, and track the status of deliveries.

- Anomaly Detection: AI systems can detect irregularities or potential disruptions (such as shipment delays or inventory shortages) and provide alerts, enabling businesses to act swiftly and prevent issues from escalating.

- Proactive Decision-Making: With real-time data at their fingertips, businesses can make informed decisions that optimise supply chain efficiency and mitigate potential disruptions.

Real-time supply chain monitoring powered by AI helps businesses stay ahead of potential problems, enhancing their ability to adapt to changing conditions.

AI-powered supply chain optimisation is transforming logistics, procurement, inventory management, and shipping. By leveraging machine learning, predictive analytics, and automation, businesses can streamline operations, reduce costs, and improve customer satisfaction. From real-time monitoring to predictive demand forecasting, AI is providing businesses with the tools they need to remain competitive in today’s dynamic market. For businesses looking to stay ahead of the curve, embracing AI-powered supply chain optimisation is no longer a luxury when it’s a necessity. Do you want to explore the AI services and solutions with Verysell AI, contact us now!