The Manufacturing Industry is undergoing a major transformation, driven by the powerful capabilities of AI. By integrating AI solutions, manufacturers are unlocking new levels of boosting efficiency, reducing operational costs, and enhancing productivity. In this article, we explore five key ways AI is revolutionizing the sector, providing innovative solutions that are shaping the future of manufacturing.

What is AI in the Manufacturing Industry?

AI in manufacturing involves leveraging machine learning (ML) and deep learning neural networks to improve production processes by enhancing data analysis and decision-making abilities. A key application of AI in manufacturing is predictive maintenance. By analyzing manufacturing data with AI algorithms, companies can predict machine failures more accurately, reducing expensive downtime in production.

In addition to predictive maintenance, AI has potential for other applications within manufacturing, such as more precise demand forecasting and minimizing raw material waste (Inavolu and Spiridonova, 2025). With the natural integration of AI and manufacturing, where human operators work closely with machines, this partnership presents significant opportunities for process optimization and innovation.

AI in the UK Manufacturing Market

AI is playing a crucial role in transforming production processes, enhancing efficiency, and driving innovation. With the rise of Industry 4.0, manufacturers are increasingly adopting AI technologies such as machine learning, predictive analytics, and automation to optimize their operations.

The global AI in manufacturing industry market is projected to reach $11.8 billion in 2024, with the market expected to grow to $84.5 billion by 2031, reflecting a compound annual growth rate (CAGR) of 32.6% from 2024 to 2031 (Business Wire, 2024). Currently, approximately 35% of manufacturing firms are adopting AI technologies, particularly in areas like predictive maintenance and quality control (Shalwa, 2024). The manufacturing industry is projected to gain $3.78 trillion from AI by 2035, underscoring the significant potential of AI to drive efficiency, reduce costs, and enhance productivity across the sector.

Key areas where AI is making an impact in the UK manufacturing sector include:

- Predictive Maintenance: AI algorithms analyze data from machines to predict failures before they happen, reducing downtime and maintenance costs.

- Smart Automation: Robotics and AI-driven automation are streamlining production lines, improving precision, and reducing human error.

- Supply Chain Optimization: AI in manufacturing industry improves demand forecasting, inventory management, and distribution, ensuring a more agile and cost-efficient supply chain.

- Quality Control: AI systems are being used to monitor and inspect production processes, ensuring consistent product quality and reducing defects.

- Energy Management: AI solutions are being utilized to monitor and manage energy usage in manufacturing plants, reducing waste and improving sustainability.

>> Read more: AI in Manufacturing: Use Cases and Examples

The UK government has also shown strong support for AI adoption in the manufacturing sector through various initiatives, such as funding for AI research and collaboration between academic institutions and industry leaders. As the demand for smarter, more efficient production grows, AI in the UK manufacturing market is expected to continue evolving, offering manufacturers the opportunity to gain a competitive edge both domestically and globally.

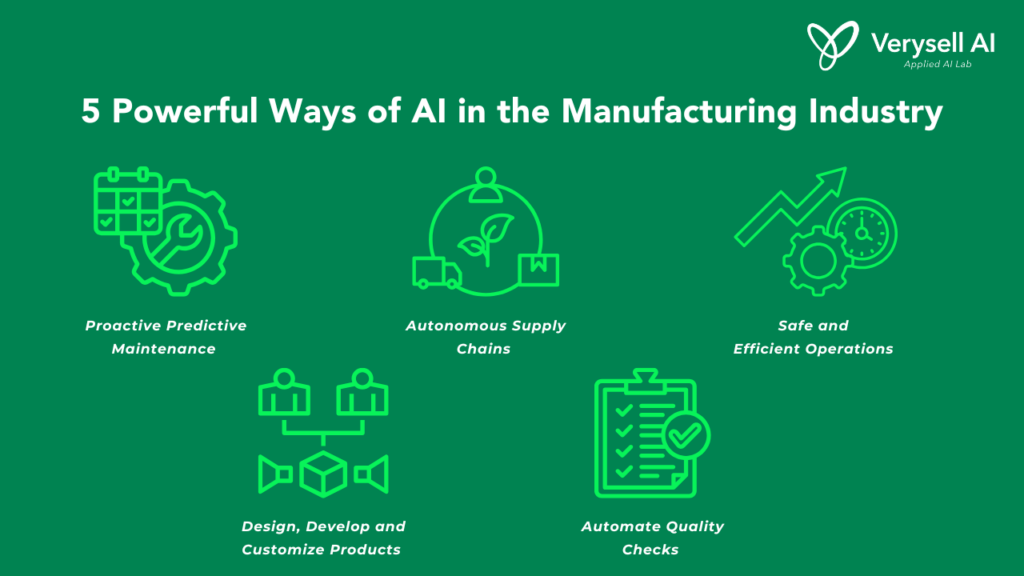

5 Powerful Ways of AI in the Manufacturing Industry

1. Proactive Predictive Maintenance

By utilizing AI to monitor and analyze data from machinery and shop floor operations, manufacturers can identify unusual patterns that help predict breakdowns. For example, AI can assess data from sources such as vibration, thermal imaging, and oil analysis to determine the health of machinery. These insights enable manufacturers to accurately forecast their needs for spare parts and consumables, as well as predict downtime for better production planning. This results in improved productivity, cost efficiency, and maintenance of equipment. Furthermore, Generative AI can amplify these benefits by reviewing documents like maintenance logs and inspection manuals, providing actionable and precise information for troubleshooting and maintenance tasks.

2. Autonomous Supply Chains

By leveraging AI in manufacturing industry, machine learning (ML), and Big Data analytics, manufacturers can achieve autonomous supply chains. This encompasses continuous, closed-loop, and fully automated processes that maintain consistent supply chain performance even in challenging conditions, requiring minimal human intervention. Moreover, industrial companies can utilize AI agents to schedule complex manufacturing lines. These agents evaluate various parameters to find the best strategies for maximizing throughput while minimizing changeover costs, ensuring timely product delivery.

3. Safe and Efficient Operations

Manufacturers, having used robots for many years, are now incorporating “cobots” into their factory settings. Unlike traditional robots that need designated space, cobots can safely collaborate with humans, performing tasks like part picking, machine operation, and quality inspections, which boosts overall productivity and efficiency. Cobots can handle a variety of tasks, including automotive assembly activities such as gluing, welding, and greasing, as well as picking and packaging finished goods. AI-powered machine vision technology plays a crucial role in facilitating this seamless integration and operation.

4. Design, Develop and Customize Products

Generative AI in manufacturing industry has the potential to transform product conceptualization by analyzing market trends, identifying regulatory changes, summarizing product research, and integrating customer feedback. These algorithms can quickly generate innovative designs that exceed the capabilities of traditional methods. As a result, manufacturers can enhance product attributes like safety, performance, aesthetics, or profitability based on their priorities. For example, in 2019, General Motors employed generative design to create a lighter and stronger seat bracket prototype for its electric vehicles.

5. Automate Quality Checks

AI transforms testing and quality control by utilizing image recognition to automatically detect equipment damage and product defects. For example, AI models trained on images of both perfect and defective products can predict whether an item requires rework or should be discarded or recycled. Additionally, AI’s analytical capabilities can identify patterns in production data, incident reports, customer feedback, and other sources, highlighting areas for improvement.

Crossing The Barrier For Using AI In Manufacturing With Verysell AI

The manufacturing sector has long recognized the potential of AI to optimize operations, enhance efficiency, and drive innovation. However, widespread adoption has been limited by various barriers, including concerns about implementation complexity, data security, and workforce readiness. Verysell AI has been active in addressing these challenges, offering comprehensive AI solutions tailored to the unique needs of manufacturers. Through innovative solutions and a commitment to security and privacy, we are paving the way for a future where AI-driven manufacturing is not just a possibility but a reality. Contact with our consulting team now!