Introduction

The manufacturing industry is undergoing a profound transformation, and at the heart of this change is Artificial Intelligence (AI). Once limited to isolated automation tools, today’s AI solutions are redefining how products are designed, built, maintained, and distributed. From smart factories to real-time predictive analytics, AI enables manufacturers to reduce costs, increase efficiency, and remain competitive in a globalized economy. This pillar page explores the comprehensive impact of AI in manufacturing, with use cases, benefits, and strategic insights.

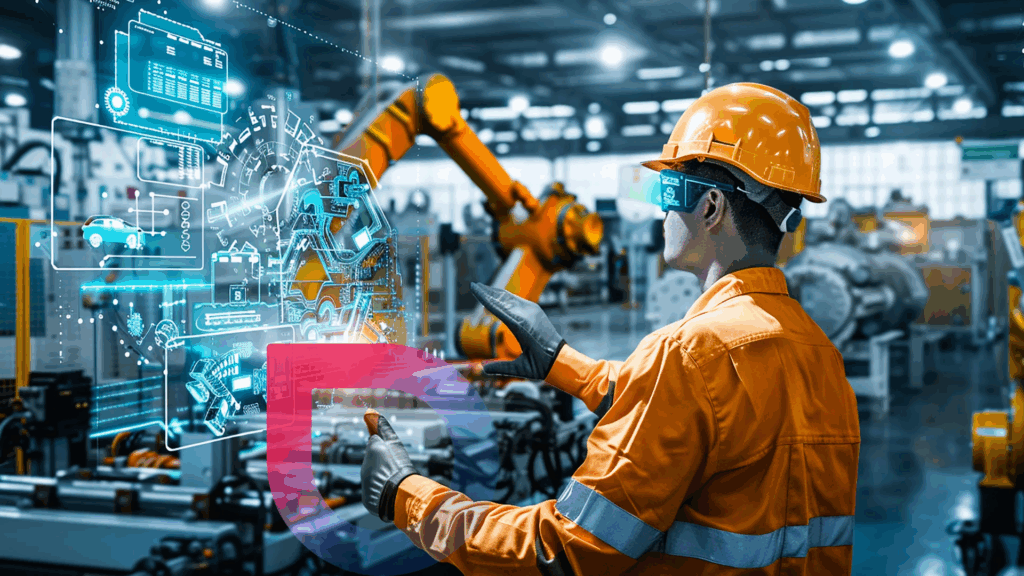

What is AI in Manufacturing?

AI in manufacturing involves the use of intelligent algorithms, particularly machine learning, deep learning, and computer vision, to improve processes throughout the production lifecycle. This technology fosters data-driven decision-making, enabling manufacturers to detect anomalies in real-time, automate complex operations, forecast demand, and optimize inventory. Additionally, AI allows for the personalization of product designs and the implementation of autonomous robotics, enhancing overall efficiency and innovation in the manufacturing sector.

>> Read more: 5 AI-powered ways to modernise manufacturing

Top Benefits of AI in Manufacturing

1. Predictive maintenance

By analyzing sensor data and equipment logs, AI predicts equipment failures before they happen – a practice known as predictive maintenance. This significantly reduces downtime and maintenance costs. AI enables predictive maintenance by analyzing data from sensors and equipment to forecast potential failures before they occur. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and reduces maintenance costs. According to FPT Software (2024), AI-driven predictive maintenance helps reduce costs for automotive manufacturing plants and enhances driver safety.

2. Quality Control

AI-powered vision systems and machine learning algorithms enhance quality control by detecting defects and inconsistencies in real-time. These systems can identify minute flaws that might be missed by human inspectors, ensuring higher product quality and reducing waste. By apply AI technology, manufacturers can increase production throughput by 20% and improve quality by as much as 35% with AI (Praxie, 2025). Moreover, AI-powered systems can adapt and learn from new data, continuously improving their accuracy and effectiveness over time. This adaptability not only streamlines the quality control process but also fosters a culture of continuous improvement within manufacturing operations.

3. Supply Chain Optimization

AI improves supply chain efficiency by forecasting demand, managing inventory, and optimizing logistics. By analyzing market trends and historical data, AI systems can predict demand fluctuations and adjust supply chain operations accordingly, reducing inventory costs and improving customer satisfaction. Additionally, AI enhances supplier relationship management by assessing supplier performance and identifying potential risks (Heinrich, 2025). By leveraging real-time data, manufacturers can make informed decisions that streamline procurement processes and ensure timely deliveries, further boosting overall supply chain resilience.

4. Enhanced Productivity

Automation of repetitive tasks through AI allows human workers to focus on more complex and creative aspects of manufacturing. AI tools assist in simplifying complex calculations and coding, leading to increased productivity and job satisfaction among employees. Furthermore, by handling mundane tasks, AI reduces the likelihood of human error, enhancing overall operational accuracy (Kodexo Labs, 2023). This shift not only fosters a more innovative work environment but also encourages continuous skill development, as employees engage in higher-value activities that require critical thinking and creativity.

5. Generative Design

AI-driven generative design tools explore numerous design possibilities based on specified parameters, enabling rapid prototyping and innovation. This approach accelerates the product development cycle and allows for the creation of optimized designs that meet specific performance criteria (Hexaware, 2024). In addition, generative design tools facilitate collaboration among teams by providing a range of design options that can be easily modified and tested. This iterative process not only enhances creativity but also ensures that the final products are both efficient and aligned with user needs, driving greater market success.

Industry-Specific Applications

1. Automotive Manufacturing

In the automotive sector, AI optimizes assembly lines, enhances predictive maintenance, and conducts autonomous quality inspections. Manufacturers like Tesla and BMW have reported efficiency improvements of 20% to 30% through AI-driven initiatives, leading to lower warranty claims and enhanced customer satisfaction (SmartDev, 2025).

2. Electronics Manufacturing

AI manages intricate tasks such as Printed Circuit Board (PCB) assembly with enhanced speed and reduced error rates (Torres, 2025). AI-powered anomaly detection systems proactively identify defects during production, safeguarding against costly recalls and ensuring consistent product quality.

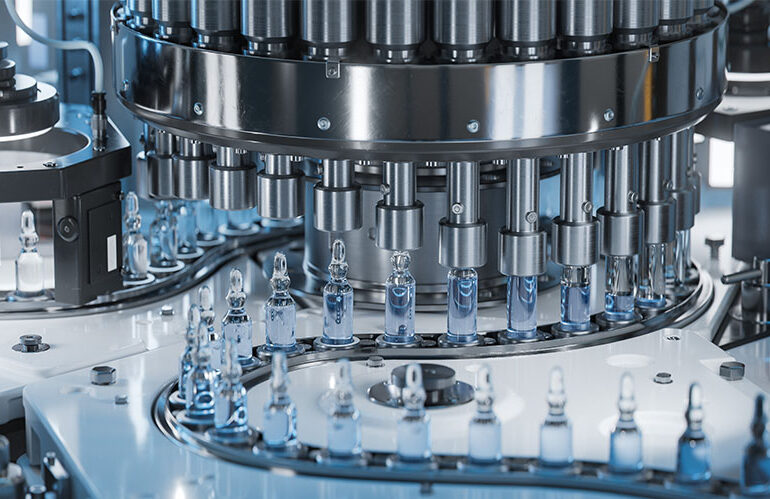

3. Pharmaceutical Manufacturing

AI ensures safety and efficiency in pharmaceutical manufacturing by monitoring production processes, predicting equipment failures, and maintaining compliance with regulatory standards. This leads to improved product quality and reduced operational risks. Moreover, AI systems can analyze vast amounts of data in real time, allowing for quick adjustments to production parameters that enhance safety protocols.

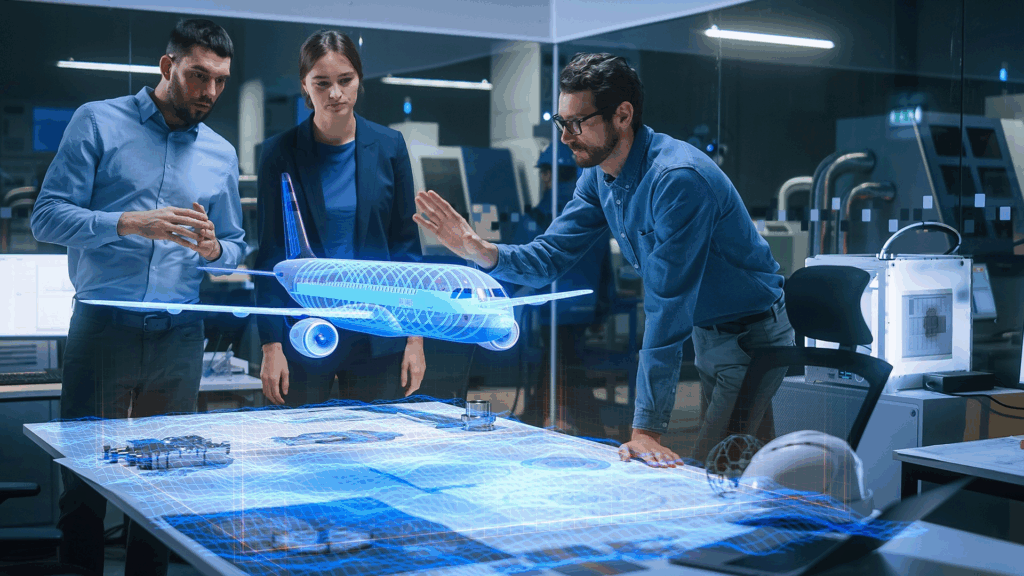

4. Aerospace Manufacturing

In aerospace, AI assists in pioneering the future of engineering by optimizing design processes, enhancing precision in manufacturing, and ensuring stringent quality standards are met. AI applications in this sector contribute to innovation and improved safety. Additionally, AI algorithms can analyze vast datasets from simulations and real-world tests, leading to more informed decision-making and reduced time-to-market for new aerospace technologies. This integration of AI not only streamlines operations but also enhances collaboration among engineering teams, driving the development of cutting-edge aircraft and systems with superior performance and reliability.

5. Consumer Goods Manufacturing

AI enhances personalization and speed in consumer goods manufacturing by analyzing consumer preferences, optimizing production schedules, and reducing time-to-market for new products. This leads to increased customer satisfaction and competitive advantage. Furthermore, AI-driven insights enable manufacturers to tailor products to specific market segments, ensuring that offerings align closely with consumer demands.

>> Explore more: 5 Exciting Ways to Transform Industry

Challenges and Considerations

While AI offers numerous benefits, its implementation in manufacturing automation comes with challenges:

- High Initial Investment: Integrating AI technologies requires significant capital expenditure, which may be a barrier for small and medium-sized enterprises.

- Data Security and Privacy: The use of AI involves handling vast amounts of data, raising concerns about data security and compliance with privacy regulations.

- Workforce Adaptation: The shift towards AI-driven processes necessitates workforce training and adaptation, as employees need to acquire new skills to work alongside AI systems.

- Integration with Existing Systems: Ensuring seamless integration of AI technologies with existing manufacturing systems and processes can be complex and time-consuming.

Conclusion

Artificial Intelligence is revolutionizing the manufacturing industry by enhancing efficiency, reducing costs, and improving product quality. From predictive maintenance to supply chain optimization, AI applications are transforming manufacturing processes across various sectors. While challenges exist, the strategic implementation of AI technologies holds the promise of a more agile, innovative, and competitive manufacturing landscape.