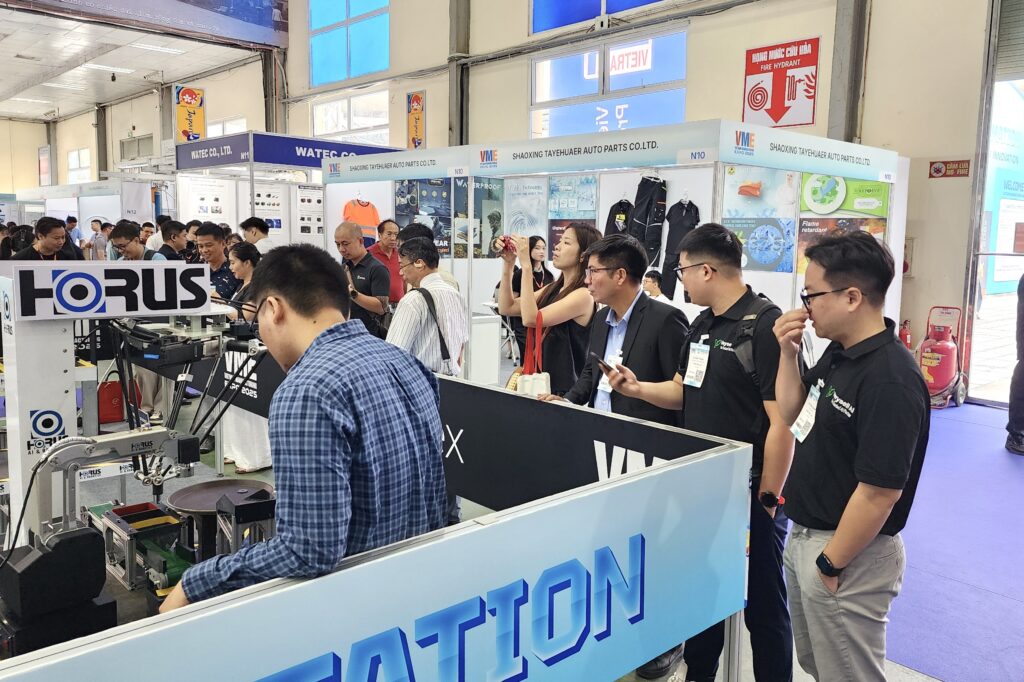

Our CTO, Toan Nguyen Huy, and AI engineers recently attended Vietnam Manufacturing Expo(VME 2025) & Vietnam-Japan Supporting Industries Exhibition 2025 in Hanoi, one of the largest manufacturing exhibitions in the region. The event welcomed over 2,400 participants from across countries and brought together around 200 brands showcasing the latest in machines, tools, and smart technology.

The team joined hundreds of other professionals in business-matching meetings and had in-depth conversations about the future of the industry with leaders and innovators. It gave a good view of how AI in manufacturing has evolved and what still needs to happen.

Outstanding Displays in Manufacturing and Automation

The show floor was packed with mechanical tools, CNC machines, robotic arms, and smart automation systems. Around 20% of the booths featured AI-related applications. Most of them focused on:

- Visual inspection

- Jig replacement automation

- Pick-and-place robots

- CNC machine optimization

While there was a lot of impressive tech on display, it was also clear that AI adoption in the sector is still in its early stages.

Observed Adoption of AI in Manufacturing: Early-Stage Integration with Growth Potential

At VME 2025, the team observed that around 20% of booths featured some form of AI application. Most of these were found in areas like visual inspection, pick-and-place robotics, CNC machines, and jig replacement automation.

While the event brought together hundreds of exhibitors across manufacturing and automation, AI was still a limited presence, focusing on a few applications:

- Primary use case: Quality Assurance (QA)

AI tools were predominantly used for visual inspection. These tools identify where defects occur but do not provide explanations for their causes, limiting their effectiveness for process optimization and root cause analysis.

- Technology scope: Basic AI methods

Implementations primarily employed computer vision or time-series analysis, with limited integration into broader production processes. Process-level AI capable of analyzing production logic or machine behavior was not evident. CK-and-place robotics, CNC machines, and jig replacement automation.

- Diagnostic capability gap

Many factories continue to rely on trial-and-error approaches to resolve production issues, indicating a lack of accessible diagnostic AI solutions.

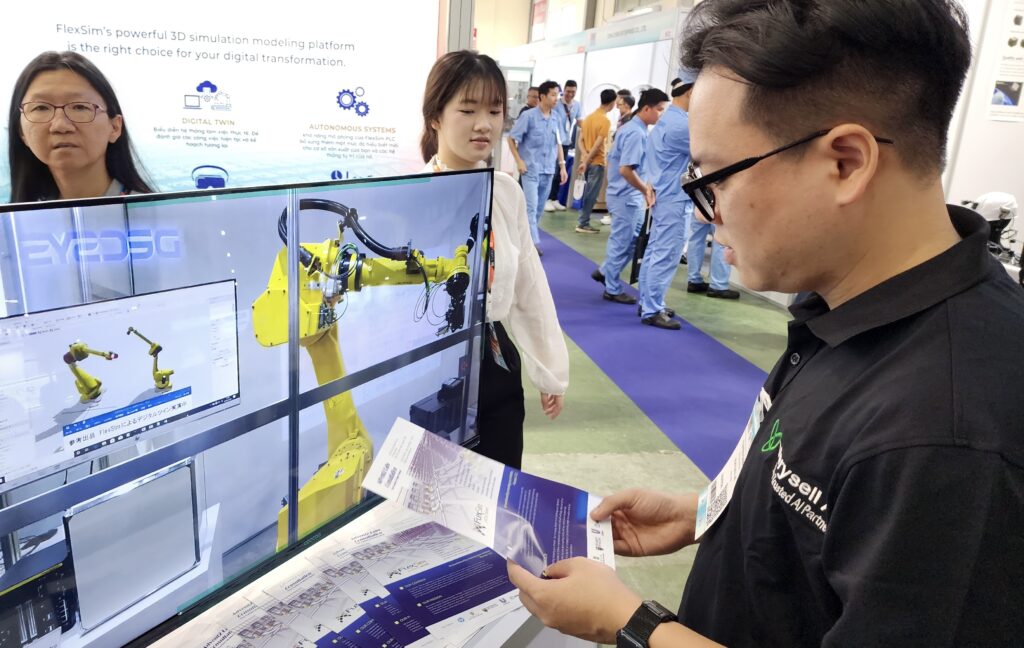

- Distinction between robotics and intelligent automation

Although robotic arms were present, they generally lacked integration with intelligent control systems, suggesting that automation has not yet fully evolved into smart automation.

It can be observed that AI hasn’t been deeply embedded into factory workflows. Only a few vendors offered AI-enabled solutions for industrial machinery, suggesting that the field is still open for development.

This reflects a broader trend: the manufacturing sector is interested in AI, but practical, scalable adoption is still early.

Current Challenges in AI Adoption

Several key gaps are holding back the progress of effective AI deployment in manufacturing environments:

- Hardware limitations

Many production machines lack the computational capacity to support local AI model inference. While data is often collected, it is typically used only for basic monitoring rather than real-time decision-making.

- On-premise infrastructure constraints

A strong preference for on-premise solutions persists across the industry. However, limited GPU availability and insufficient AI-ready infrastructure present significant barriers to adoption.

- Manual operations in time and resource management

Core operational tasks such as shift scheduling and machine runtime management are still predominantly handled manually. While automation could enhance efficiency, AI applications in this area remain underdeveloped.

- Edge AI trade-offs

Deploying AI at the edge frequently requires compromises between model complexity and execution speed, posing ongoing challenges to achieve both accuracy and responsiveness.

Production optimization, in particular, remains a highly underutilized application of AI. In other words, there is clear demand, but execution remains difficult due to these foundational constraints.

Opportunities for Applied AI with Verysell AI

At Verysell AI, we’re approaching these challenges in two main ways.

- Computer vision tools that address immediate QA needs, such as defect detection, quality control, safety monitoring, and worker movement analysis. These are modular and can be adapted to various production environments.

- LLMs (large language models) in manufacturing contexts can support internal knowledge retrieval, assist with maintenance documentation, and streamline operator instructions. Our 10-week product-ready program helps factories experiment with this approach in a controlled, low-risk way.

- Ready-made solutions like our customer service chatbot can be integrated into customer-facing or admin-heavy environments.

Looking ahead, we’re also investing in physical AI, focusing on the future of robotics and precision manufacturing, where we believe intelligence and automation will converge more deeply.

Looking Ahead: From Proof-of-Concept to Production

VME 2025 made one thing clear: AI in manufacturing is moving forward, but slowly. As manufacturers explore AI across their operations, the shift from experimentation to execution is becoming critical.

The road ahead calls for tighter collaboration between AI providers and industrial teams, leaner infrastructure demands, and a focus on delivering clear business value. At Verysell AI, we’re committed to helping manufacturers cross the gap: turning AI ambition into real-world impact.