Quality control (QC) tradititionally in production lines has relied heavily on human inspectors, manual checks, and traditional testing equipment (Fibre2Fashion, 2008). However, these methods are often slow, prone to error, and incapable of keeping up with the fast-paced demands of modern manufacturing.

Enter AI-driven quality control with computer vision. By integrating artificial intelligence (AI) and machine learning with computer vision technology, manufacturers can significantly enhance the accuracy, speed, and efficiency of their quality control processes (DuraLabel, 2025). This approach is transforming industries like automotive, electronics, food processing, and pharmaceuticals, offering unprecedented benefits that go beyond traditional methods. In this blog post, we will explore five key ways AI and computer vision are revolutionizing quality control in manufacturing.

>> Click here to explore top use cases of AI in Manufacturing

1. Quality Control: Automated Defect Detection

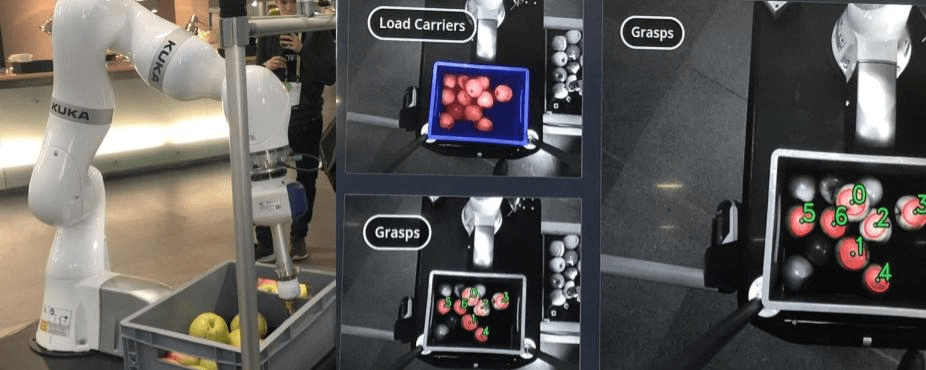

The most significant advantage of AI-powered quality control is its ability to automate defect detection in real-time (Jain, 2024) Traditional methods typically rely on manual inspections, where human inspectors look for defects like scratches, dents, or incorrect alignments. However, human error is inevitable, and as production speeds increase, it becomes increasingly difficult for human inspectors to spot all potential issues.

AI-driven computer vision systems, on the other hand, use high-resolution cameras and image processing algorithms to continuously monitor the production line. These systems can detect even the smallest defects that might go unnoticed by human eyes. Machine learning models are trained to recognize different types of defects by analyzing thousands of images of both good and bad products (Gupta et al., 2023).

Once trained, the AI system can instantly identify any anomalies in the production process and alert operators in real-time. This eliminates the need for manual inspection and drastically reduces the risk of defective products reaching consumers. Furthermore, AI systems can analyze product quality at a much faster rate than human inspectors, leading to higher throughput and efficiency in the production line.

2. Consistency and Precision

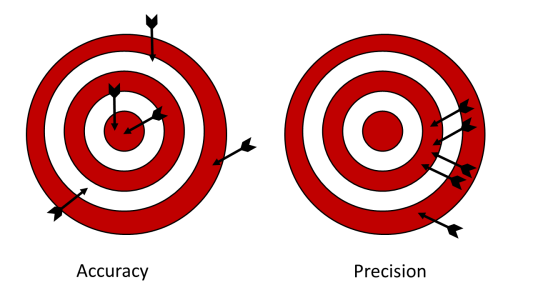

In manufacturing, even the smallest deviation in product quality can lead to significant issues down the line. Inconsistent product quality can result in customer dissatisfaction, increased returns, and costly recalls (Sadikin, 2023). AI-powered quality control ensures consistency and precision, something that is difficult to achieve with human inspectors.

Computer vision systems can measure minute differences with remarkable accuracy. They use advanced algorithms to compare every product against a predefined standard. This ensures that every item leaving the production line adheres to the same high-quality standards. Additionally, machine learning models can continuously improve their accuracy over time by learning from new data, making them more reliable as the system matures. By automating the quality control process, manufacturers can reduce human variability and ensure that every product meets the required specifications, resulting in a consistent product that builds customer trust and satisfaction.

3. Predictive Maintenance and Reduced Downtime

One of the most innovative aspects of AI-driven quality control is its ability to not only monitor product quality but also assess the health of production equipment (Hasan et al., 2025). Through predictive maintenance, AI systems can identify potential failures in machinery before they happen, preventing unplanned downtime.

Computer vision systems can analyze visual data to detect early signs of equipment wear or malfunction, such as overheating components, misalignments, or parts that are at risk of failure (Castellaw, 2025). AI algorithms can then alert operators or maintenance teams, enabling them to take corrective action before a failure occurs.

This predictive approach to maintenance is far more cost-effective than reactive maintenance. By addressing issues before they cause equipment breakdowns, manufacturers can avoid costly repairs, reduce downtime, and maintain optimal production efficiency. Furthermore, the overall lifespan of machines can be extended, contributing to long-term savings and better resource utilization.

>> Explore here to achieve the proactive predictive maintenance way

4. Enhanced Data Analytics and Process Optimisation

AI and computer vision systems do more than just identify defects and monitor equipment. These systems also collect vast amounts of data during the manufacturing process, providing valuable insights into production trends, efficiency, and potential areas for improvement (Owen and Hannah, 2021).

Through machine learning, the AI systems can analyze this data to detect patterns, identify inefficiencies, and recommend process optimizations. For example, AI can pinpoint where in the production line defects are most likely to occur and suggest adjustments to improve efficiency and reduce waste. It can also track trends in defect rates over time, providing actionable insights that help manufacturers improve product designs, material choices, and even the layout of the production line.

Additionally, AI can integrate with other aspects of the supply chain, offering real-time tracking and visibility of materials and products, helping manufacturers optimize inventory management, reduce waste, and improve forecasting. The ability to leverage data in real-time allows manufacturers to make informed, data-driven decisions that enhance overall productivity and reduce operational costs.

5. Scalability and Flexibility

As the demand for products increases, manufacturers often face challenges in scaling their operations while maintaining high-quality standards (Zhang et al., 2024). Traditional quality control methods may require additional inspectors, more manual processes, and increased overhead costs to handle higher volumes. However, AI-driven quality control systems offer a scalable solution.

These systems are highly flexible and can be easily adapted to accommodate different production lines, product types, and quality standards. Whether a manufacturer is producing small batches of custom products or large volumes of mass-produced goods, AI systems can adjust to the scale of the operation without compromising quality.

Furthermore, AI-based systems can be rapidly deployed across multiple production lines or even different factories, enabling companies to maintain consistent quality standards across various locations. This scalability is particularly beneficial for multinational manufacturers looking to ensure uniform product quality worldwide.

The Future of AI-Driven Quality Control

The future of AI-driven quality control is incredibly promising. As AI and computer vision technologies continue to advance, they will become even more accurate, faster, and more integrated into the entire manufacturing process. The ongoing development of machine learning algorithms will further enhance the ability to predict defects, optimize production processes, and ensure consistent product quality.

Moreover, AI-driven quality control systems will likely become more affordable and accessible to small and medium-sized enterprises (SMEs). With the democratization of AI technology, even companies with limited budgets will be able to implement advanced quality control solutions, leveling the playing field in terms of product quality and production efficiency.

In addition to improving quality control, AI and computer vision will continue to drive innovation in manufacturing processes, leading to the development of smarter factories that are more automated, efficient, and adaptable to market demands.

Conclusion

AI-driven quality control with computer vision is no longer a futuristic concept, it is already transforming the manufacturing industry. By automating defect detection, ensuring consistency, predicting maintenance needs, optimizing processes, and offering scalability, AI-powered systems are enabling manufacturers to produce higher-quality products faster and at lower costs.

For manufacturers looking to stay competitive in a rapidly evolving industry, adopting AI and computer vision for quality control is not just a smart choice; it is an essential step toward future-proofing their operations. With the continued advancements in AI, the next generation of quality control systems promises even greater efficiencies and capabilities, driving further innovations in manufacturing.