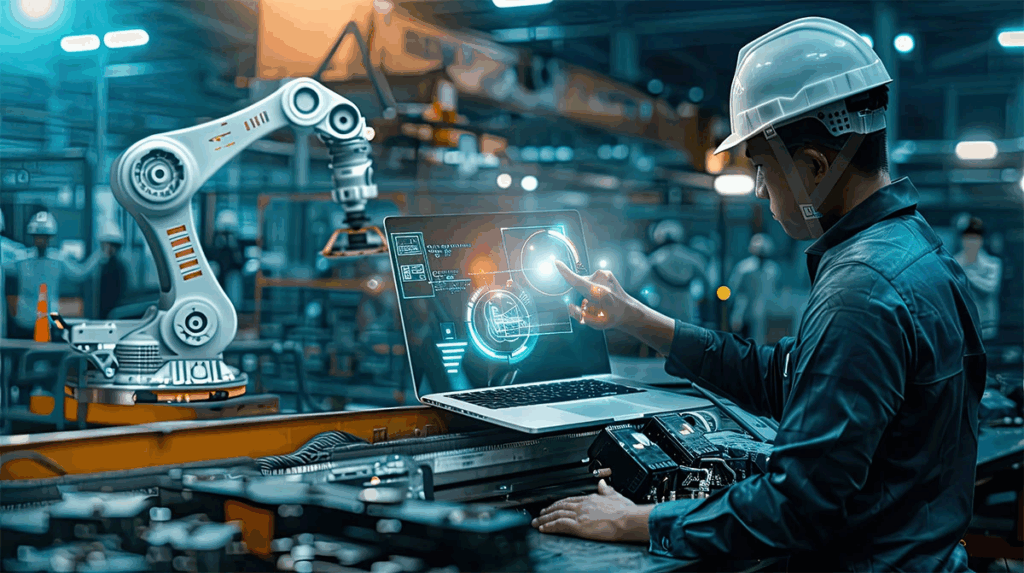

Manufacturing AI has emerged as a transformative force, offering new ways to optimize production processes, reduce operational costs, and enhance product quality. Artificial intelligence in manufacturing is no longer a futuristic concept but a present-day reality that is reshaping the industry. In this post, we will explore the top 15 AI-driven manufacturing solutions that can help businesses improve efficiency and drive innovation.

>> Click here to explore top use cases of AI in Manufacturing

Manufacturing AI

Manufacturers are frequently facing different challenges such as unexpected machinery failure or defective product delivery. Leveraging AI and machine learning, manufacturers can improve operational efficiency, launch new products, customize product designs, and plan future financial actions to progress on their digital transformation.

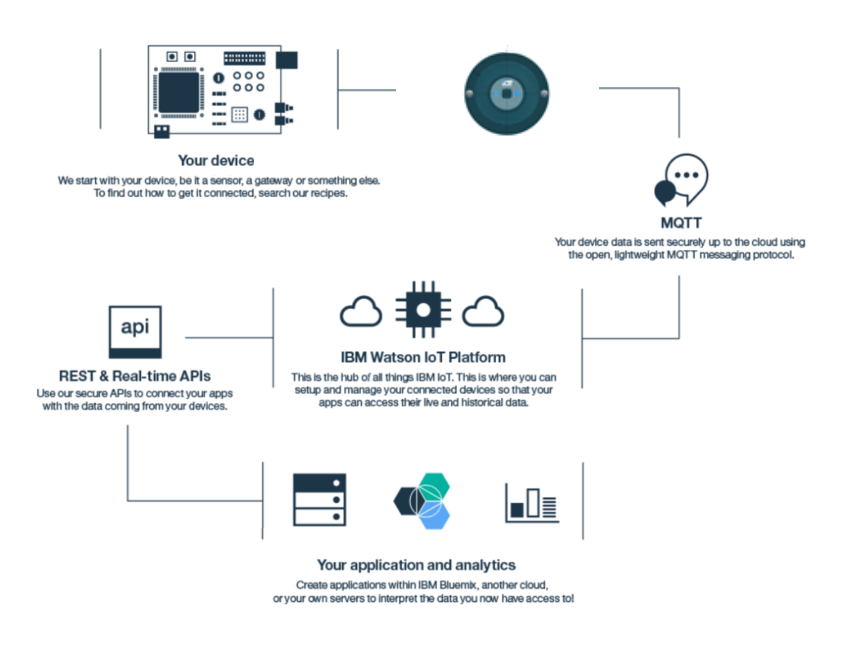

1. IBM Watson IoT

IBM Watson IoT is one of the most well-known AI-driven manufacturing solutions for manufacturing. It helps manufacturers harness the power of industrial IoT platforms, combining AI and machine learning to predict equipment failures, optimise production processes, and increase operational efficiency. With advanced analytics, Watson IoT can monitor machines in real-time, analyse data, and predict when maintenance is needed, helping to reduce downtime and extend the life of equipment.

Key Features: Predictive maintenance tools, real-time monitoring and process optimisation

2. Siemens MindSphere

MindSphere from Siemens is an industrial IoT platform powered by AI that enables manufacturers to optimize their production processes and improve operational efficiency. MindSphere connects devices, machines, and sensors, and integrates data into a centralised system that provides actionable insights. The platform uses AI to predict equipment failures, enhance supply chain efficiency, and improve energy management.

Key Features: Predictive analytics, connected machine learning and real-time data visualisation

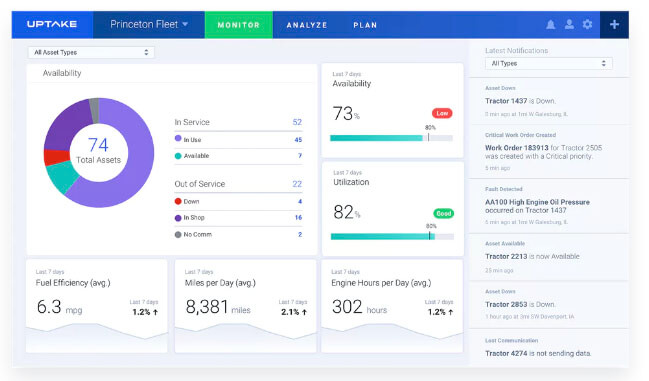

3. Uptake

Uptake uses AI to provide actionable insights for industrial operations. By analyzing machine data, Uptake predicts failures and suggests actionable solutions. This AI-driven platform is particularly beneficial for fleet management and heavy equipment industries, helping companies extend the lifespan of their machinery while reducing the risk of breakdowns.

Key Features: Predictive maintenance, AI-driven fleet management and machine performance analysis

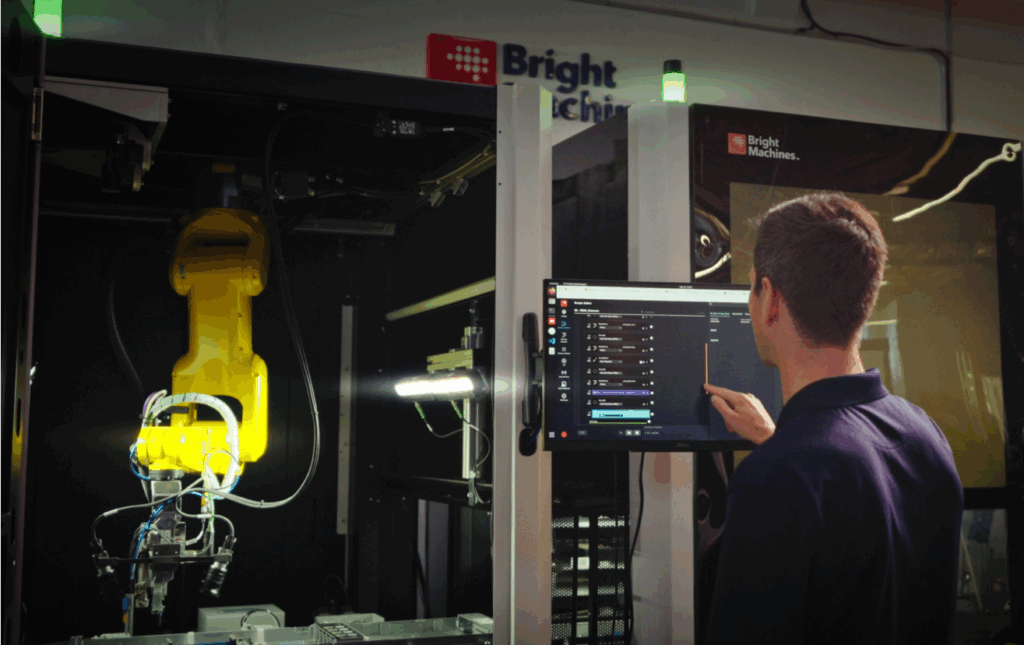

4. Bright Machines

Bright Machines is an AI-powered platform that combines machine learning with robotics to automate manufacturing workflows. The platform is designed to improve quality control, speed up production, and reduce waste. Its AI models analyze production processes in real-time to identify inefficiencies and suggest improvements.

Key Features: Robotic automation, real-time process analysis and AI-driven quality control

5. FANUC

FANUC’s FIELD (FANUC Intelligent Edge Link and Drive) System is an industrial AI solution designed to optimize manufacturing operations through machine learning. By collecting data from machines on the factory floor, the system analyzes performance, predicts maintenance needs, and provides actionable insights to increase production efficiency.

Key Features: Machine learning integration, predictive maintenance and data-driven production optimisation

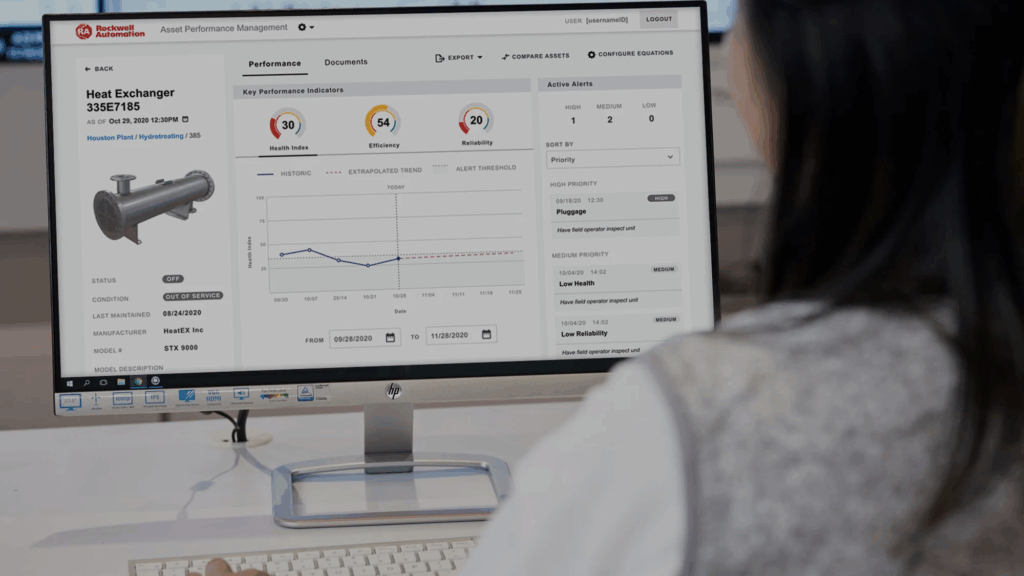

6. Rockwell Automation’s FactoryTalk Analytics

FactoryTalk Analytics by Rockwell Automation is a comprehensive suite of AI and analytics tools that enable manufacturers to gain deep insights into their production operations. The platform allows for predictive maintenance, performance optimization, and real-time decision-making by using advanced AI algorithms and big data analytics.

Key Features: Performance optimisation, predictive analytics and real-time decision-making

7. Porsche Digital’s AI-Driven Manufacturing System

Porsche Digital has developed an AI-driven manufacturing system that optimises production schedules, quality assurance, and supply chain management. The system uses machine learning to predict supply chain bottlenecks, improve efficiency, and maintain high-quality standards throughout the production process.

Key Features: AI-driven production scheduling, supply chain optimiation and quality assurance automation

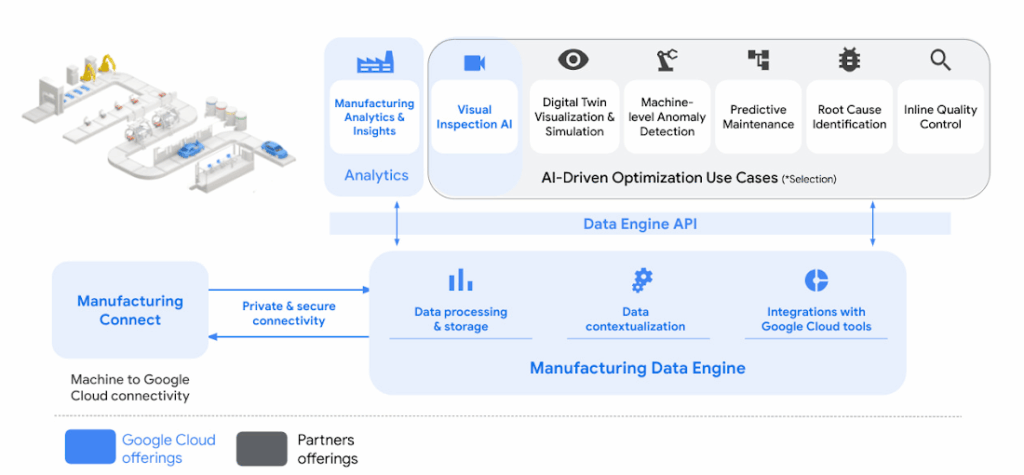

8. Google Cloud AI for Manufacturing

Google Cloud AI offers machine learning models and AI tools specifically designed for the manufacturing sector. These tools allow manufacturers to optimize inventory management, predict equipment failures, and analyse production data. By integrating AI for production optimisation into their workflows, manufacturers can improve efficiency, reduce waste, and better manage resources.

Key Features: Machine learning models for inventory management, predictive maintenance and data analytics for production optimisation

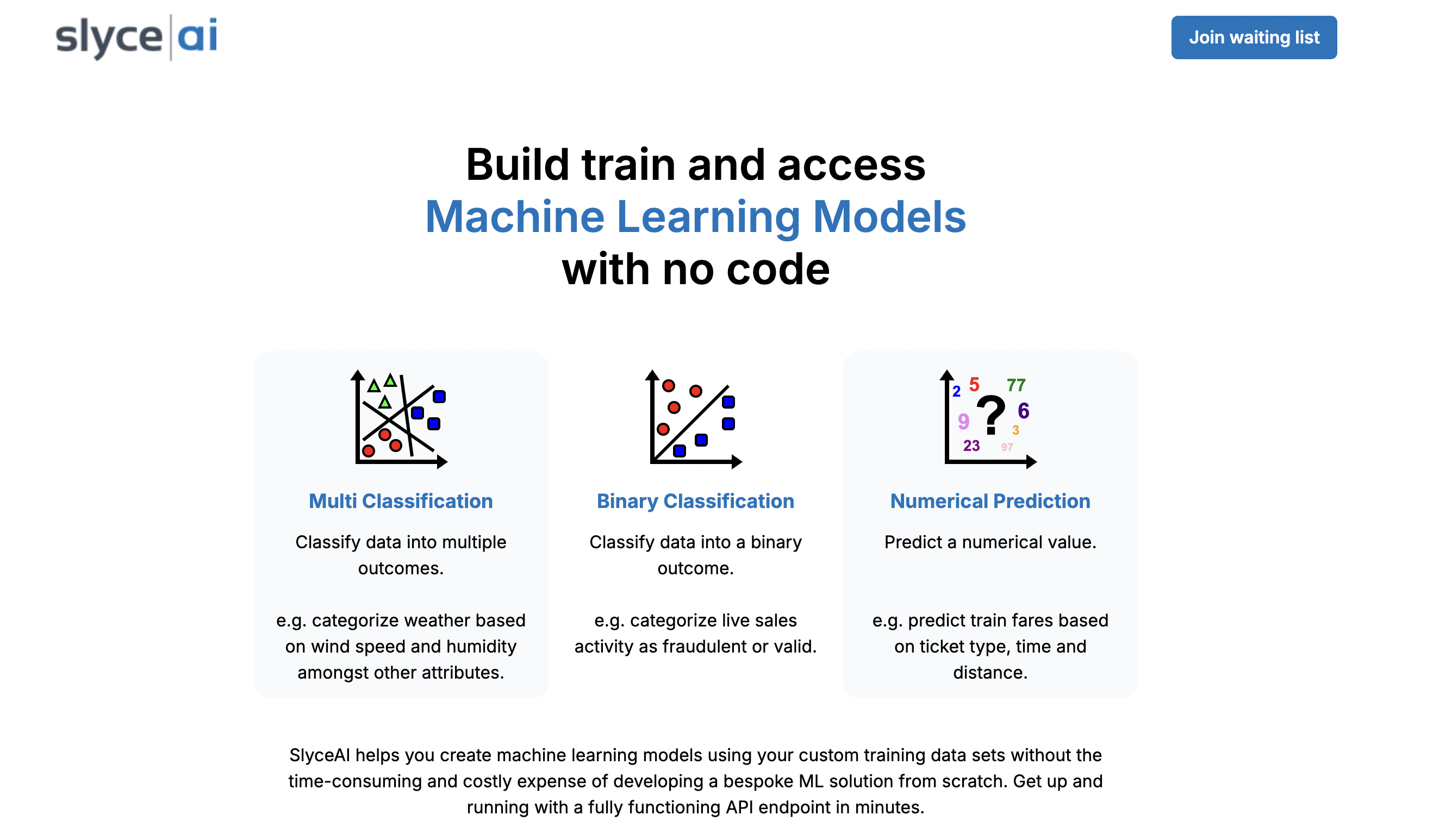

9. Slyce AI

Slyce AI specialises in visual recognition and machine learning technologies to help manufacturers improve their quality control processes. By using image recognition software powered by AI, Slyce can identify defects, discrepancies, and quality issues in products on the production line, enhancing product consistency and reducing human error.

Key Features: Visual recognition technology, quality control automation and defect detection

10. DataRobot

DataRobot provides an automated machine learning platform that can be applied to a variety of manufacturing scenarios, from supply chain optimization to predictive maintenance. The platform automates the process of building and deploying machine learning models, enabling manufacturers to leverage AI without requiring extensive technical expertise.

Key Features: Automated machine learning, predictive analytics and supply chain optimisation

Incorporating Manufacturing AI tools into production processes is no longer optional for businesses looking to remain competitive. These tools enable manufacturers to optimise operations, reduce costs, and improve product quality. By leveraging the power of AI, companies can make smarter decisions, increase productivity, and ensure the longevity of their equipment. The 10 tools highlighted in this post are just a glimpse of the vast potential AI-driven manufacturing solutions hold for the manufacturing sector. As the industry continues to evolve, those who adopt and integrate AI for production optimization into their workflows will undoubtedly lead the charge toward a more efficient and innovative future.