Artificial Intelligence has emerged as one of the most transformative forces in modern manufacturing. From predictive maintenance and computer-vision inspection to autonomous quality monitoring and intelligent supply chain coordination, AI promises unprecedented efficiency and resilience. Yet, despite this potential, many manufacturers struggle to translate early Proof of Concept (PoC) success into a stable, factory-wide deployment.

The core issue is not the lack of innovation. It is the gap between controlled PoC testing and real production conditions. A PoC built on clean datasets or isolated test rigs rarely reflects the complexity found on an actual shop floor, where machines vary in age, data sources are fragmented, and operators are under constant pressure to maintain throughput. This article explores why so many AI PoCs stall before production, highlights the three non-negotiable factors that determine deployment success, and presents a structured 10-week approach that accelerates the journey from concept to customer-ready solution.

>> Click here to read our AI POCs with 6-layer framework on our previous webinar!

1. Why Manufacturing AI PoCs Rarely Scale

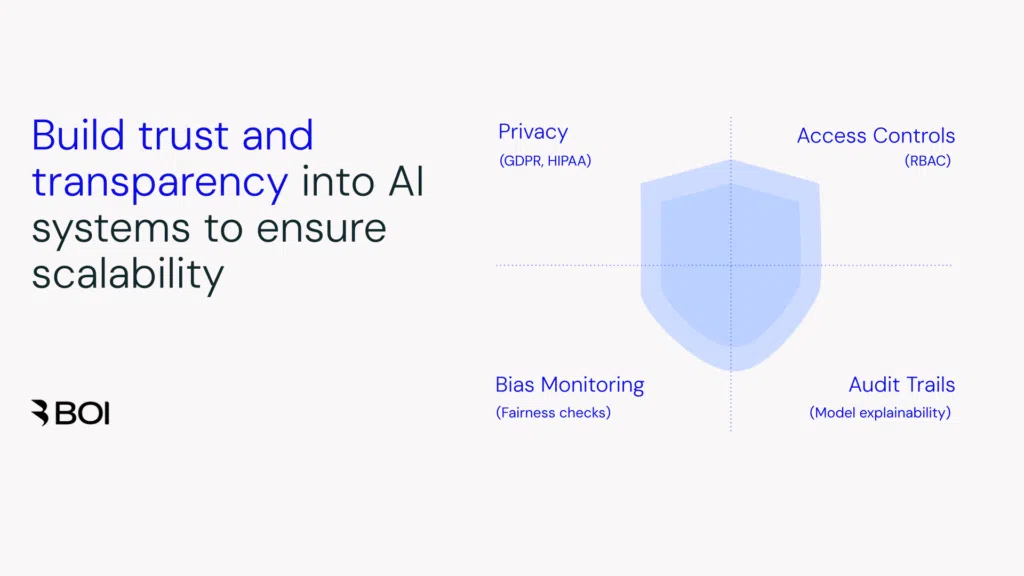

Most PoCs demonstrate technical feasibility, but factories need more than a working model. They need a solution that respects operational constraints, integrates with legacy infrastructure, and enhances operator workflows not disrupt them. According to BOI (2025), it is important to build trust and transparency into AI systems to ensure scalability from privacy, access controls, bias monitoring and audit trails

Across industries, a familiar pattern emerges whenever AI is introduced into manufacturing. Models perform impressively in controlled lab environments, but once they encounter the complexity of real production, their reliability declines. As performance issues surface, operators become hesitant, slowing adoption across the factory. Over time, the initial enthusiasm fades and the business loses momentum.

To break this cycle, manufacturers must understand why PoCs struggle when scaled to live operations. Identifying the root causes from inconsistent data to integration constraints and workflow misalignment that provides the clarity needed to design more resilient solutions. With the right approach, organizations can shift from one-off experiments to sustainable, production-ready AI systems.

2. Data Quality and Consistency: The Hidden Challenge of Real-World Machines

Manufacturing environments generate large volumes of data, but the data is rarely uniform. Every machine, sensor, and subsystem reflects a different era of engineering. Some vendors follow strict data formatting standards, while others provide limited metadata or highly compressed logs.

This leads to three key issues:

2.1 Training Data vs. Production Data Are Fundamentally Different

Training data is typically historical, curated, and cleaned to help models perform well, but production data presents a very different reality. Live factory data is often noisy, inconsistent, filled with outliers, and prone to timestamp mismatches, especially when equipment ages or sensors begin to drift. These variations are unavoidable in real operations and place far greater demands on the robustness of an AI system. Any model trained only on ideal datasets will inevitably struggle when exposed to the unpredictable conditions of the shop floor.

2.2 Variability Is the Norm, Not the Exception

Consider a production line where sensors behave in fundamentally different ways: one streams data every 10 milliseconds, another reports only when its state changes, and a third periodically misses readings because of vibration or electromagnetic interference. This uneven flow of information reflects the true conditions in which AI must operate. If a model is trained or tested only on uniform, predictable inputs, it will fail to perform reliably when confronted with such variability.

To succeed in real manufacturing environments, AI systems must be stress-tested against these inconsistencies rather than shielded from them. Scaling becomes possible only when the model has already proven itself under difficult, messy situations. If testing is limited to ideal conditions, unexpected errors will show up the moment the solution is deployed.

3. System Integration: The True Backbone of AI Deployment

Even a highly accurate AI model cannot generate real business value unless it integrates smoothly into the existing production ecosystem. Modern factories operate on interconnected layers of technology, where each system plays a critical role in maintaining operational continuity. PLCs manage equipment behavior, SCADA platforms deliver real-time visibility, MES coordinates production activities, and ERP systems connect operations to broader business workflows. Alongside these, local databases store years of historical records that support analysis, compliance, and continuous improvement.

When a PoC is built in isolation, running on a separate laptop or cloud instance without a clear integration plan, it cannot deliver meaningful impact. Without automated data flow, system compatibility, and real-time connectivity, the solution becomes impossible to scale and ultimately stalls. For AI to move from concept to production, integration architecture must be designed from the beginning, not treated as an afterthought.

3.1 Integration Challenges Are Often Underestimated

Manufacturers often assume that integration can be handled after the PoC is approved, but this is where most of the real engineering effort lies. Moving from a standalone prototype to a production-ready system requires far more than model accuracy. It demands secure data pipelines, low-latency communication, and compatibility with a wide range of industrial protocols already in use on the factory floor.

Beyond technical alignment, teams must navigate network limitations and strict industrial security policies that govern how data is transmitted, stored, and accessed. These requirements add complexity that cannot be retrofitted once the PoC is complete. Treating integration as a core activity from the start is essential for achieving scalable, reliable deployment.

3.2 Legacy Systems Are Not Easily Replaceable

Unlike software environments, industrial equipment cannot be upgraded every few years. Many PLCs or motion controllers operate reliably for decades, but they use protocols not designed for modern AI workloads. Deployment success depends on respecting legacy systems, not fighting them. Manual data extraction still common in many early PoCs, which is not a viable long-term approach for any manufacturing operation.

To move from experimentation to true production readiness, AI systems need autonomous data ingestion, standardized transformation processes, automated model outputs, and closed-loop feedback mechanisms that continually refine performance. These elements create a stable, repeatable pipeline that supports real-time decision-making and operational consistency. Without this foundation, even the best-performing model remains confined to a single machine or isolated test setup, unable to scale across the factory.

4. A Structured Path: The 10-Week Product-Ready Validation Program

Many AI projects fail because they operate as open-ended research initiatives. The 10-week Product-Ready Program by Verysell AI replaces this uncertainty with a clear, predictable roadmap.

>> Watch our latest webinar to explore our AI PoCs in 10 week!

4.1 Week 1: Define Constraints and Baseline Conditions

Identify the limitations of machinery, data availability, network architecture, site security, and workflow dependencies. This ensures that the team designs for reality not assumptions.

4.2 Weeks 2–4: Integration Feasibility and System Mapping

Before investing time in refining AI models, it is essential to confirm that the new software can successfully communicate with the existing factory systems. This includes establishing reliable connections to PLCs, integrating with SCADA or MES platforms, and ensuring compatibility with both on-premise servers and cloud services. Validating integration at this early stage helps identify technical gaps and prevents costly rework later in the project. By resolving these concerns upfront, manufacturers can accelerate development and ensure the solution is truly ready for production deployment.

4.3 Weeks 5–7: Model Adaptation Using Real Production Data

Models are evaluated against noisy, inconsistent, real-time data coming directly from the factory floor. This phase hardens the AI so it can withstand operational challenges.

4.4 Weeks 8–9: Operator-Centric Refinements

Technicians and line operators should be actively involved in refining the solution throughout development, especially in areas such as UI and UX design, alert logic, decision-support flows, and hardware ergonomics. Their practical insights ensure that the tool aligns with real working conditions rather than assumptions made during the PoC phase. When users feel the system supports their daily tasks and reduces complexity, adoption becomes significantly smoother. Ultimately, long-term success depends on human-centric design that respects operator workflows and enhances their effectiveness.

4.5 Week 10: Production-Ready Blueprint & Go-Live Strategy

Deliver a validated solution architecture, integration plan, operating guidelines, and deployment roadmap tailored to the client’s factory environment. By compressing validation into a defined 10-week sprint, manufacturers can rapidly determine feasibility, reduce risk, and move from conceptual discussions to actionable outcomes.

5. Customer-Centric Manufacturing: The Future Competitive Advantage

Traditional manufacturing focuses on standardization and consistency. Today’s manufacturing leaders must move beyond this to meet rising expectations around personalization, rapid configuration, and real-time responsiveness.

AI enables this shift by turning factories into flexible, insight-driven systems.

Verysell AI supports this transition through:

- Predictive maintenance that prevents unexpected downtime and increases equipment availability

- Digital twin simulations that allow teams to test layout changes, production flows, and scenario variations virtually

- AI-driven to intelligent supply chain coordination that synchronizes materials, logistics, and demand forecasting

- Context-aware production scheduling that adapts automatically to customer needs and operational conditions

- Quality prediction and defect prevention models that elevate consistency and reduce waste

These solutions create a manufacturing environment that is not only efficient but customer-centric—an advantage that is increasingly critical in high-competition industries.

The Path Forward: Transform Your Operations with Verysell AI

For many manufacturers, the biggest obstacle is not vision but execution. Legacy systems, inconsistent data, and complex operational environments can make transformation feel overwhelming. But with the right methodology and technical expertise, AI can deliver measurable, practical value within weeks not years. Contact Verysell AI today to discuss your challenges, explore suitable use cases, and begin your path toward a smarter, more adaptive, AI-powered manufacturing operation.

If your organization is ready to transition from theoretical PoCs to real-world, scalable AI systems, Verysell AI can guide you through every stage of deployment. We help you validate feasibility quickly, reduce deployment risks, and integrate AI with legacy equipment while designing operator-friendly solutions that fit seamlessly into daily workflows. By leveraging predictive maintenance, computer-vision inspection, autonomous quality monitoring, and intelligent supply chain coordination, we enable you to accelerate time-to-value and modernize operations without disrupting production.