For decades, predictive maintenance strategies in manufacturing and industrial operations have relied on fixed schedules, manual inspections, and standardized routines. While preventive maintenance has certainly reduced catastrophic breakdowns compared to reactive maintenance, it is inherently limited by its reliance on predetermined intervals rather than real conditions. As equipment becomes more complex and production lines integrate advanced digital systems, organizations are recognizing that scheduled checks alone cannot support the level of reliability, efficiency, and cost control demanded by modern operations.

>> Read the blog post about AI in the manufacturing!

This shift has paved the way for predictive maintenance, where artificial intelligence transforms how organizations monitor equipment, anticipate failures, and optimize performance. Moving from time-based tasks to data-driven automation marks one of the most significant operational transformations in modern industry. This article explores how predictive maintenance has evolved, the impact of AI-powered automation, key enablers, and what organizations must do to realize its full potential.

1. What is Predictive Maintenance?

According to IBM (2025), In order to decide when predictive maintenance should be carried out, predictive maintenance assists in forecasting the equipment’s possible future state. Maintenance strategies, including predictive, reactive, and preventive maintenance, depend on factors like asset cost, criticality, usage patterns, and the impact of failure on safety and finances. Predictive maintenance, being proactive, improves upon preventive maintenance by offering real-time insights into equipment condition rather than relying solely on historical data.

This approach allows corrective actions only when necessary, thus minimizing maintenance costs and downtime. By utilizing time series data on historical performance and failures, businesses can foresee potential equipment issues and optimize maintenance schedules for increased reliability. Predictive maintenance strategies stand out due to the range of real-time monitoring techniques used, such as ultrasonic acoustics, thermal imaging, lubrication analysis, and vibration monitoring. For example, rising temperatures may signal airflow issues, while unusual vibrations can indicate misaligned parts, providing early warnings of defects that might otherwise go unnoticed.

2. The Limitations of Scheduled Maintenance

Traditional scheduled maintenance is built on a simple principle: perform routine inspections and replace parts at predefined intervals to prevent unexpected failures. While effective in reducing downtime, this method operates based on statistical averages rather than equipment-specific behavior.

2.1 Over-Maintenance & Under-Maintenance

Components may be replaced prematurely even when they remain in good condition. This leads to unnecessary spare-parts consumption, additional labour hours, and avoidable operational interruptions. For industries running 24/7 lines, the cost compounds rapidly. Conversely, failures may occur before the next scheduled inspection, especially in equipment subject to fluctuating loads, environmental variability, or aging infrastructure. These unexpected breakdowns disrupt production, increase repair costs, and introduce safety risks.

2.2 Lack of Real-Time Visibility & Dependence on Human Expertise

Scheduled checks only offer snapshots of equipment health. They cannot detect subtle performance degradation, long-term drift in sensor accuracy, or micro-vibrations that signal early defect patterns. Experienced technicians often diagnose issues using intuition developed over years of hands-on work. While invaluable, this expertise is difficult to scale, especially as many organizations face workforce shortages and retiring skilled labour. As a result, companies are asking a critical question: How can maintenance shift from a time-based model to a condition-based, intelligence-driven system that adapts to actual machine behavior?

3. The Rise of Predictive Maintenance

Predictive maintenance monitors equipment performance and condition in real time to forecast when failures are likely to occur. Instead of replacing components on a fixed schedule, maintenance is triggered by data indicating genuine degradation.

Key advantages include:

- Reduced downtime through early detection of anomalies.

- Higher equipment lifespan by avoiding unnecessary overhaul.

- Optimized spare parts inventory with accurate failure forecasting.

- Improved worker safety by identifying hazards before they escalate.

- Increased production output due to uninterrupted operations.

Why AI Is the Game Changer

While traditional PdM relies on threshold-based alerts or basic statistical models, AI-powered predictive maintenance elevates capabilities to a new level. Machine learning algorithms can detect subtle patterns that humans or classical systems would never identify.

Advanced Pattern Recognition: AI can analyse high-frequency signals such as vibration, temperature, acoustic emissions, torque, pressure and detect micro-anomalies invisible to the human eye. For example:

- A bearing failure predicted weeks earlier from a slight shift in vibration frequency.

- Motor deterioration detected through harmonic distortion analysis.

- Pump cavitation spotted through audio spectrogram changes.

Adaptive Learning: AI models continuously improve as more data is collected. As operating environments change such as new load patterns or equipment upgrades with the system automatically adjusts. This makes AI suitable for dynamic production environments where conditions rarely remain static.

Autonomous Decision Making: In advanced deployments, AI not only predicts failures but recommends or triggers corrective actions, such as adjusting machine parameters, scheduling maintenance automatically, triggering procurement workflows for parts, and reallocating workloads across machines. This transition from prediction to automation is what defines the new generation of maintenance strategies.

Scalability Across the Factory: Unlike human-driven checks, AI can monitor hundreds of sensors, machines, and lines simultaneously. Multi-asset facilities benefit from integrated dashboards, anomaly clustering, and enterprise-wide visibility.

Integration with Digital Twins: Digital twins provide virtual replicas of equipment. When combined with AI-driven predictive analytics, companies can simulate failures, optimize maintenance timing, and test interventions without interrupting production. Across automotive, semiconductor, chemicals, food processing, and heavy industries, this intelligence layer is becoming essential infrastructure.

4. Transitioning from Scheduled Checks to AI Automation

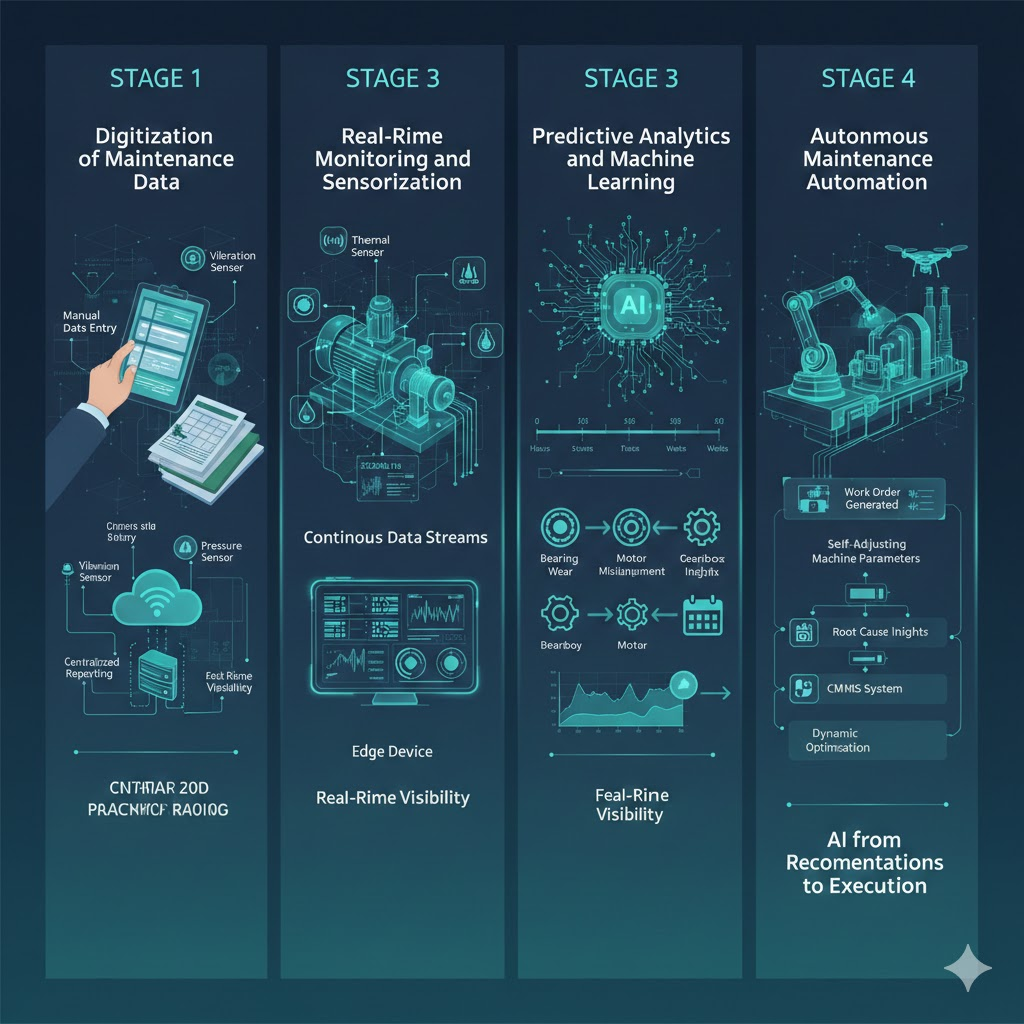

Stage 1: Digitization of Maintenance Data: Organizations move from paper-based or spreadsheet processes to digital maintenance logs. This foundational shift enables improved traceability, centralized reporting, and early analytics on historical trends. However, this phase still depends heavily on manual data entry.

Stage 2: Real-Time Monitoring and Sensorization: IoT sensors, edge devices, and SCADA/MES integrations start providing continuous data streams. This replaces periodic checks with real-time visibility. Common sensors include vibration, thermal, humidity, ultrasonic, current, and pressure sensors.

Stage 3: Predictive Analytics and Machine Learning: At this stage, AI models identify patterns linked to failure modes. Typical use cases are predicting bearing wear, identifying misalignment, detecting lubrication issues, and forecasting degradation of motors, compressors, pumps, and gearboxes. Prediction windows range from hours to weeks, allowing maintenance teams to plan effectively.

Stage 4: Autonomous Maintenance Automation: This is the future state, where AI shifts from recommendations to execution maintenance tasks initiated automatically, work orders generated in CMMS systems, self-adjusting machine parameters, robotic inspections,, auto-generated root cause insights, and dynamic optimization of the entire production ecosystem.

5. What Makes AI-Driven Predictive Maintenance Successful?

AI adoption is not only a technical challenge. It requires operational readiness, reliable data pipelines, and close collaboration between technicians, engineers, and IT/OT teams.

High-quality, stanardized data: AI is only as accurate as the data it receives. Factories often struggle with inconsistent sensor quality, non-standardized data formats across machines, missing timestamps, noise in production data, and manual data extraction before AI deployments. Automated, standardized pipelines are essential. This includes integrating data from PLCs, SCADA/MES, historians, IoT sensors, and manual logs into a unified platform.

Robot infrustructure: A reliable predictive maintenance ecosystem requires edge processing for low-latency analysis, secure cloud or hybrid environments, scalable storage for high-frequency time-series data, and strong OT cybersecurity practices. AI workloads, particularly those involving complex models, are resource-intensive and must be supported accordingly.

Cross-functional collaboration: Technicians, operators, and engineers bring contextual understanding that AI cannot learn from raw data alone. Successful deployments involve capturing tacit knowledge from experienced workers, refining alert thresholds collaboratively, validating model outputs on the shop floor, and ensuring recommendations fit real operational workflows.

Clear Integration with Maintenance Processes: AI insights must trigger meaningful actions such as CMMS integration for work orders, alerts routed to the correct teams, procurement sync for spare parts availability, and automatic shutdowns for safety-critical failures. Without seamless integration, AI becomes just another dashboard rather than an operational catalyst.

A Phased, Practical Rollout: Rather than attempting a full-factory transformation, organizations succeed by starting with one asset class, validating value, and expanding horizontally. A controlled rollout reduces risk and accelerates ROI.