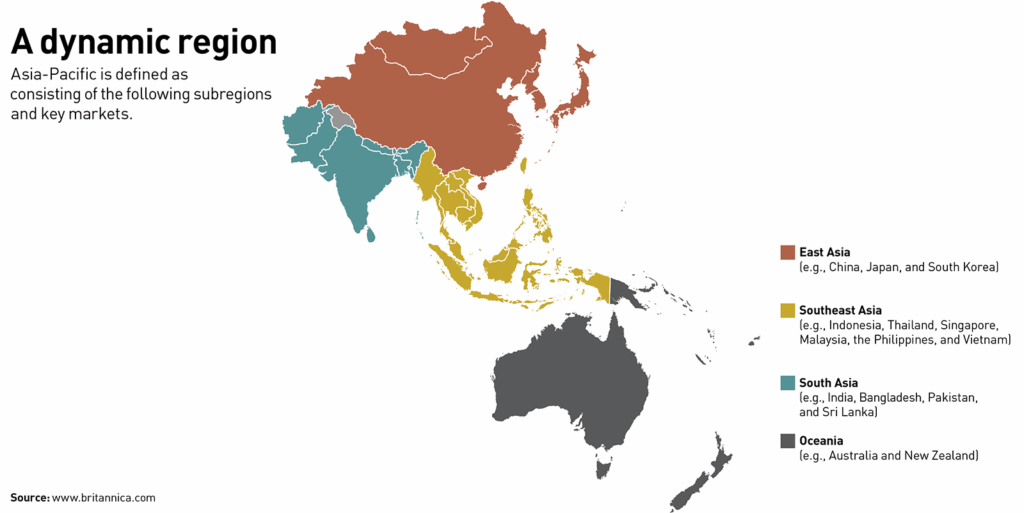

In the Asia-Pacific (APAC) region, AI adoption is fast becoming a competitive necessity for manufacturers. According to CFOtech Asia (2025), throughout the APAC region, about 38% of total AI budgets are allocated to Generative AI, surpassing the global average of 33%. However, despite this strong enthusiasm, many organizations continue to struggle with aligning AI initiatives to their broader strategic objectives and seamlessly integrating AI into existing operational workflows. As supply chains become more fragile, customer demand becomes more varied, and labor costs rise, manufacturers stand at a pivotal crossroads. Those embracing digital transformation, especially deploying AI, are gaining distinct advantages in productivity, quality, and resilience. Those who delay risk falling behind.

This article examines why AI adoption is no longer optional for APAC manufacturing firms, what benefits and challenges lie ahead, and what steps companies should take to integrate AI as a core competitive asset.

1. Growing Pressure from Market and Operational Realities

Manufacturers in APAC face rising wage costs, supply volatility, and more exacting quality standards from global customers. Traditional methods such as manual inspections, fixed schedules for maintenance, reactive responses are increasingly inadequate. AI can automate defect detection, continuously monitor equipment health (predictive maintenance), and optimize production lines in real time, reducing waste and downtime.

In addition, statistics show a high expection of digital transformation from manufacturers in APAC area. According to the 2024 Manufacturing Vision Study by Zebra Technologies, 68% of APAC manufacturers expect AI to drive growth by 2029, up from 46% in 2024. This jump reflects growing acknowledgement that digital transformation anchored by AI is central to competitiveness. 87% of APAC manufacturers say that digital transformation is a priority; yet over 80% report struggles in innovation pace and implementation.

2. Key Benefits of AI Adoption in Manufacturing

Here are concrete benefits making AI adoption a necessity, not just an advantage:

- Predictive Maintenance & Cost Reduction: AI helps forecast failures before they occur, reducing unplanned downtime and maintenance costs.

- Enhanced Quality Control: Real-time defect detection using computer vision and AI analytics leads to improved product consistency.

- Supply Chain Optimization: AI models can predict demand fluctuations, optimize inventory levels, and improve logistics resilience.

- Labor and Skills Shortages Mitigation: With rising labor costs and difficulties securing skilled operators, AI can augment human work, automating repetitive tasks, supporting operators, helping retrain workforce.

- Sustainability and Efficiency Gains: AI supports energy optimization, waste minimization, and process efficiency. All increasingly critical under regulatory and customer pressures. Manufacturers are investing in smart manufacturing to address sustainability goals.

3. Challenges to AI Implementation in APAC Manufacturing

While benefits are compelling, several challenges make AI adoption non-trivial:

- Skill & Talent Gaps: Many manufacturers report difficulty finding and retaining talent capable of deploying and maintaining AI systems. Skills shortages are cited by over 72% of APAC enterprises as a significant concern, leading to delays in digital transformation and product development, according to CFOtech Asia (2025).

- Integration of IT and OT: Bridging operational technology (OT) on the factory floor with information technology (IT) systems is often complex and costly. Legacy machinery may lack connectivity or generate low data quality.

- Scaling Beyond Pilots: It’s one thing to experiment with AI; scaling across plants and geographies, integrating with enterprise systems, ensuring reliability is another. Many manufacturers struggle with this.

- Cost of Implementation & ROI Uncertainties: Upfront investment in hardware, sensors, data infrastructure, and staff training can be high. Returns may not be immediate, especially for firms with thin margins.

- Regulatory, Security, and Data Governance: Concerns over data privacy, industrial cybersecurity, regulatory compliance, and ethical use of AI are rising. Firms must build robust governance structures. According to Rockwell Automation (2025), cybersecurity ranks as the second biggest external risk, with 49% of manufacturers planning to use AI for cybersecurity in 2025, up from 40% in 2024

4. Why Delay Is Risky?

Given the above pressures and benefits, delaying AI adoption is risky:

- First-Mover Advantages: Manufacturers that invest early in AI gain operational efficiencies, supply chain resilience, and quality superiority. These advantages can compound, making it harder for late adopters to catch up.

- Customer Expectations Rising: Global customers increasingly expect consistent quality, speed in delivery, transparency, and sustainability. Falling short can mean losing market share.

- Regulation and Standards: As governments in APAC tighten regulations around environmental impact, worker safety, and quality standards, AI can help ensure compliance. Firms lacking AI capabilities may find themselves non-competitive or non-compliant.

- Talent Attraction: Technologically advanced firms attract better talent. Manufacturers embracing AI look more attractive to engineers, data scientists, and operators seeking modern work environments.

5. Actionable Steps for APAC Manufacturers

To ensure successful AI adoption and turn it into a competitive necessity rather than risk, manufacturers should:

- Develop a Clear AI Strategy

Define key use cases (predictive maintenance, quality control, demand forecasting, etc.), align AI projects with business KPIs, and set measurable goals. - Start with High-Impact Pilots

Test AI in discrete areas where ROI is easier to measure, then use those wins to build momentum for broader rollout. - Build or Acquire Skills

Invest in training programs, partnerships with universities or vendors, or hire data science / AI engineering talent. Also invest in cross-training factory workers. - Modernize Data Infrastructure

Ensure OT systems can feed usable data (sensor networks, IoT, edge devices), invest in data quality, security, and analytics platforms. - Focus on Integration

Connect AI models to enterprise systems (ERP, MES, supply chain tools) so insights lead to action—not stay isolated in dashboards. - Governance, Security & Ethical Use

Develop policies for data privacy, cybersecurity, explainability, and ethical AI usage. Also ensure compliance with local laws and industry standards. - Monitor & Iterate

Use metrics to track outcomes (downtime reduction, quality yield, waste, lead times), iterate based on feedback, and scale what works.

Conclusion

In the APAC manufacturing sector, AI adoption is no longer an optional investment, but a competitive necessity. Firms that act now can improve efficiency, quality, innovation, and resilience. Those that delay risk falling behind.

If you are a manufacturer looking to accelerate your digital transformation and embed AI across your operations, Verysell AI can help. Our team specializes in AI-powered solutions tailored to manufacturing contexts: predictive maintenance, real-time monitoring, data-driven quality inspections, and enterprise-grade AI deployment.

Contact us today to explore how your manufacturing operations can become not just efficient, but truly competitive in the AI era.