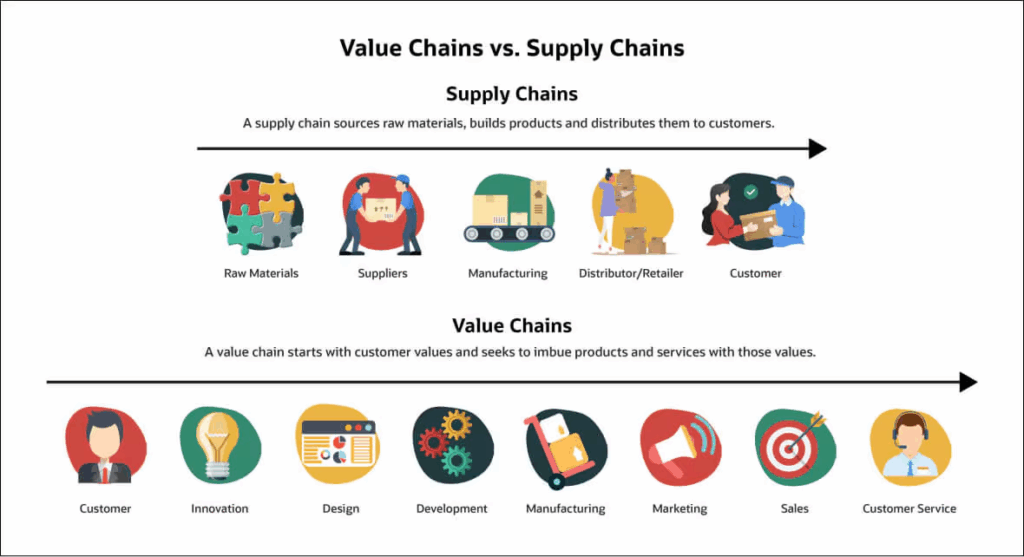

Autonomous supply chain visibility is redefining how organizations perceive, manage, and optimize complex global supply networks. Instead of relying on delayed reports, fragmented dashboards, or manual reconciliation, businesses are moving toward systems that continuously sense, interpret, and act on supply chain signals in real time. This shift is not simply a technological upgrade; it represents a fundamental change in how decisions are made, risks are managed, and value is created across procurement, manufacturing, logistics, and distribution.

>> Read more about the best 5 AI-powered forecasting to boost supply chain efficiency!

1. The Limits of Traditional Supply Chain Visibility

For many organizations, “visibility” still means retrospective insight. Data analytics is collected from ERP systems, transportation management platforms, warehouse systems, and supplier reports, then aggregated into dashboards that describe what has already happened. While useful for reporting and compliance, this model struggles in volatile environments.

Traditional visibility models suffer from four structural weaknesses. First, they are reactive rather than proactive. Issues such as supplier delays or port congestion are identified after service levels have already been affected. Second, data is fragmented across systems and partners, creating blind spots at handoff points. Third, interpretation depends heavily on human analysts, which limits scalability and speed. Finally, decision-making is often decoupled from execution, meaning insights do not automatically translate into corrective actions. In an era of geopolitical uncertainty, climate disruption, and demand volatility, these limitations expose organizations to unnecessary cost and risk.

2. From Visibility to Autonomy

Autonomous supply chain visibility goes beyond seeing what is happening. It focuses on understanding why events are happening, predicting what is likely to happen next, and deciding what actions should be taken, with minimal human intervention.At its core, autonomy is enabled by the convergence of artificial intelligence, real-time data ingestion, and decision automation.

Sensors, transactional systems, external data feeds, and partner platforms continuously stream signals into a unified intelligence layer. Machine learning models interpret these signals, detect anomalies, forecast outcomes, and recommend or execute responses based on predefined policies. This does not eliminate human oversight. Instead, it shifts human involvement from manual monitoring to strategic supervision, exception handling, and policy design.

3. Key Capabilities of Autonomous Supply Chain Visibility

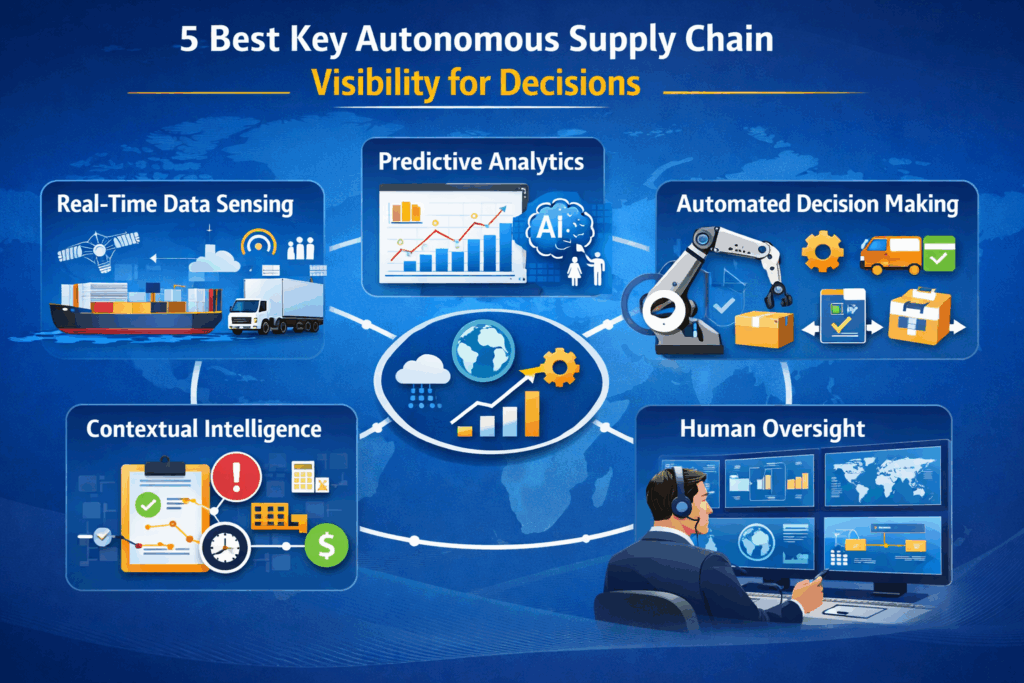

Continuous data sensing: Data is ingested in real time from internal systems, IoT devices, logistics providers, suppliers, and external sources such as weather, traffic, and geopolitical alerts. This creates a living digital representation of the supply chain. As conditions change, the system continuously updates its understanding without waiting for manual reporting cycles.

Contextual intelligence: Raw data is enriched with business context. A delayed shipment is not just a timestamp anomaly; it is evaluated against customer priority, inventory buffers, contractual penalties, and downstream production schedules. This enables decisions to be based on business impact rather than isolated operational metrics.

Predictive awareness: Advanced analytics forecast disruptions before they fully materialize. For example, early indicators of supplier stress or port congestion can trigger preemptive mitigation actions. This forward-looking capability shifts supply chain management from reactive firefighting to proactive risk prevention.

Automated decisioning: Based on policies and risk thresholds, the system can autonomously reroute shipments, adjust inventory allocations, reschedule production, or trigger supplier escalation workflows. Decisions are executed at machine speed while remaining aligned with predefined business rules and constraints.

Human-in-the-loop governance: High-impact or high-risk decisions are escalated to human decision-makers, ensuring accountability, compliance, and trust. This governance model balances automation efficiency with human judgment for critical or exceptional scenarios.

4. How Autonomous Supply Chain Visibility Works in Practice

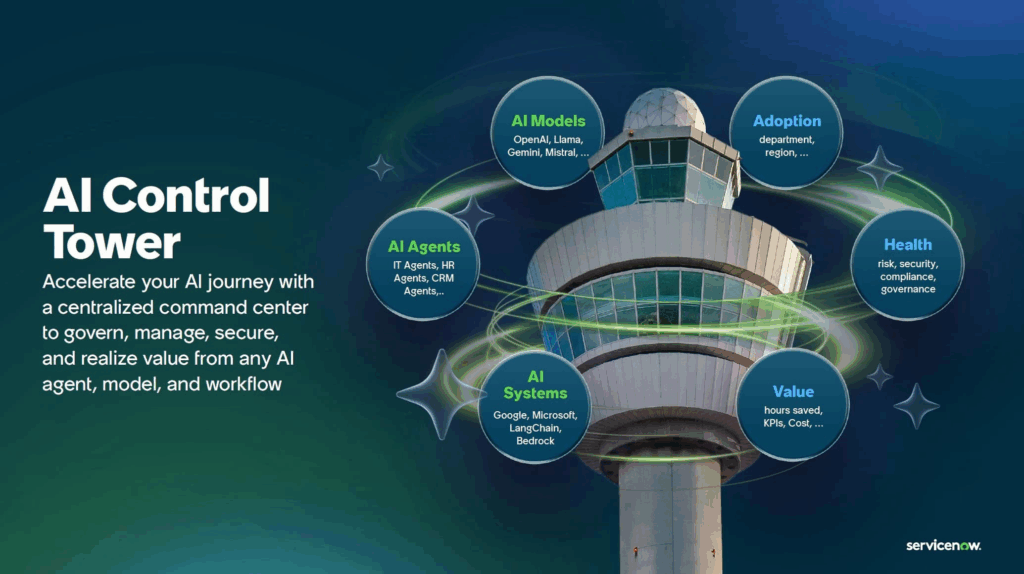

In practice, autonomous visibility is often implemented through an intelligent control layer that sits above existing operational systems. Rather than replacing ERP, TMS, or WMS platforms, it connects to them, harmonizing data and orchestrating decisions across the ecosystem.

A typical workflow begins with real-time signal detection. For instance, a sudden increase in transit times on a key trade lane is detected through carrier data and external congestion indicators. The system evaluates the impact on customer orders, inventory positions, and service-level agreements. Predictive awareness models estimate the likelihood of missed delivery commitments. Based on predefined rules, the system may automatically propose alternative routes, switch carriers, or rebalance inventory across distribution centers. In mature implementations, these actions can be executed automatically, with full auditability and rollback mechanisms.

5. Business Value Across the Supply Chain

The value of autonomous supply chain visibility is realized across multiple dimensions of performance. By enabling faster, more informed decisions, organizations can respond to disruptions with greater precision and confidence. At the same time, continuous intelligence improves alignment between operational execution and strategic business objectives, driving sustainable competitive advantage.

Resilience and risk reduction: By identifying disruptions earlier and responding faster, organizations reduce the likelihood of cascading failures. This is particularly critical in multi-tier supply networks where second- or third-tier supplier issues often go unnoticed until it is too late. Early intervention enables mitigation actions to be deployed before localized issues escalate into systemic supply chain breakdowns.

Cost optimization: Automation reduces expediting costs, inventory buffers, and manual planning effort. Decisions are optimized holistically rather than locally, balancing transportation cost, inventory holding cost, and service levels. This integrated optimization approach delivers sustainable cost savings without compromising operational reliability or customer experience.

Service-level improvement: Real-time prioritization ensures that high-value customers and critical orders receive preferential treatment during disruptions, improving reliability and satisfaction. This targeted response helps protect revenue, strengthen customer trust, and reduce the impact of unavoidable disruptions.

Operational efficiency: Planners and analysts spend less time chasing data and more time focusing on strategic improvements, supplier development, and scenario planning. As a result, organizations achieve higher productivity while reducing decision latency and operational friction.

6. Autonomous Visibility Versus Traditional Control Towers

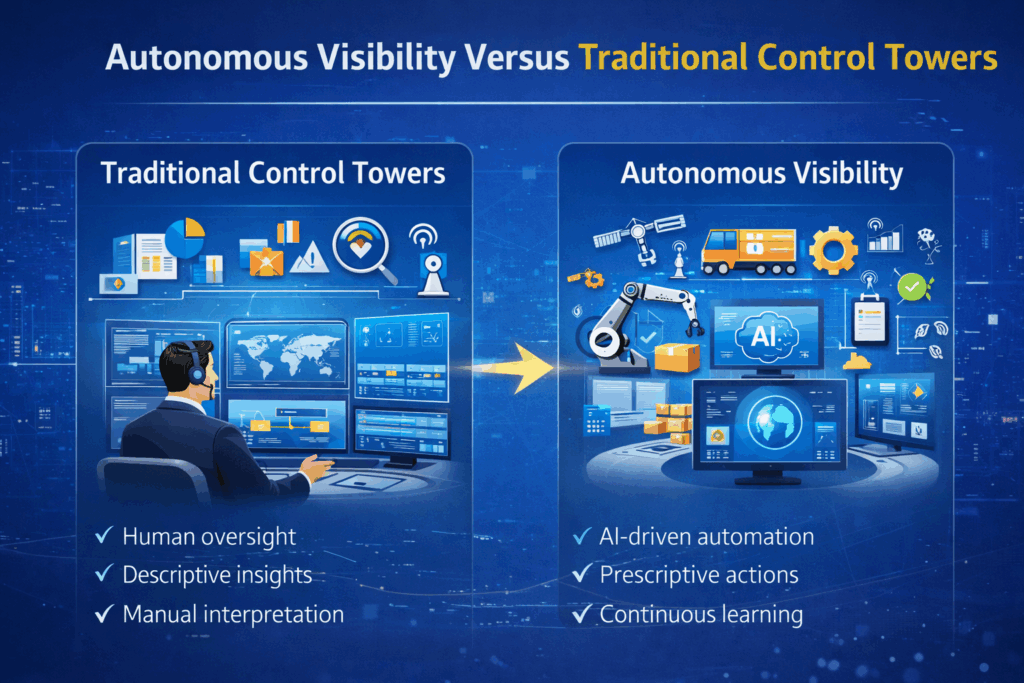

Traditional supply chain control towers represented an important step forward by centralizing data and providing a single source of truth. However, most control towers remain descriptive rather than prescriptive. Autonomous supply chain visibility can be seen as the evolution of the control tower concept. Instead of dashboards that require constant human interpretation, autonomous systems actively reason about the data and initiate actions.

The difference is not just technological but philosophical: the system is designed to act, not merely to inform. This evolution is particularly important as supply chains become more complex and interconnected. Human-centric models do not scale linearly with complexity, while AI-driven systems can process vast volumes of signals simultaneously.

7. Organizational Readiness and Change Management

Technology alone is not sufficient. Autonomous supply chain visibility requires organizational readiness across people, processes, and culture. Teams must be willing to trust algorithmic recommendations and shift away from manual intervention as the default response. This often requires phased adoption, starting with decision support and gradually increasing automation as confidence grows. Clear communication, training, and success metrics are essential to avoid resistance and shadow processes. Leadership plays a critical role in framing autonomy as an enabler of better decision-making rather than a threat to roles or expertise.

As autonomous capabilities mature, supply chains will increasingly function as self-regulating systems. Instead of reacting to disruptions, organizations will design networks that continuously adapt to changing conditions. Scenario simulation, digital twins, and reinforcement learning will further enhance the system’s ability to learn from past outcomes and improve over time. In this future, competitive advantage will not come from having more data, but from having systems that can interpret data faster, decide more intelligently, and act more consistently than human-only models.

Conclusion

Autonomous supply chain visibility represents a decisive shift from hindsight-driven reporting to foresight-driven action. By combining real-time data, artificial intelligence, and automated decisioning, organizations gain the ability to sense disruptions early, respond intelligently, and continuously optimize performance. While the journey requires careful governance and organizational change, the payoff is a supply chain that is more resilient, efficient, and responsive in an increasingly uncertain world.