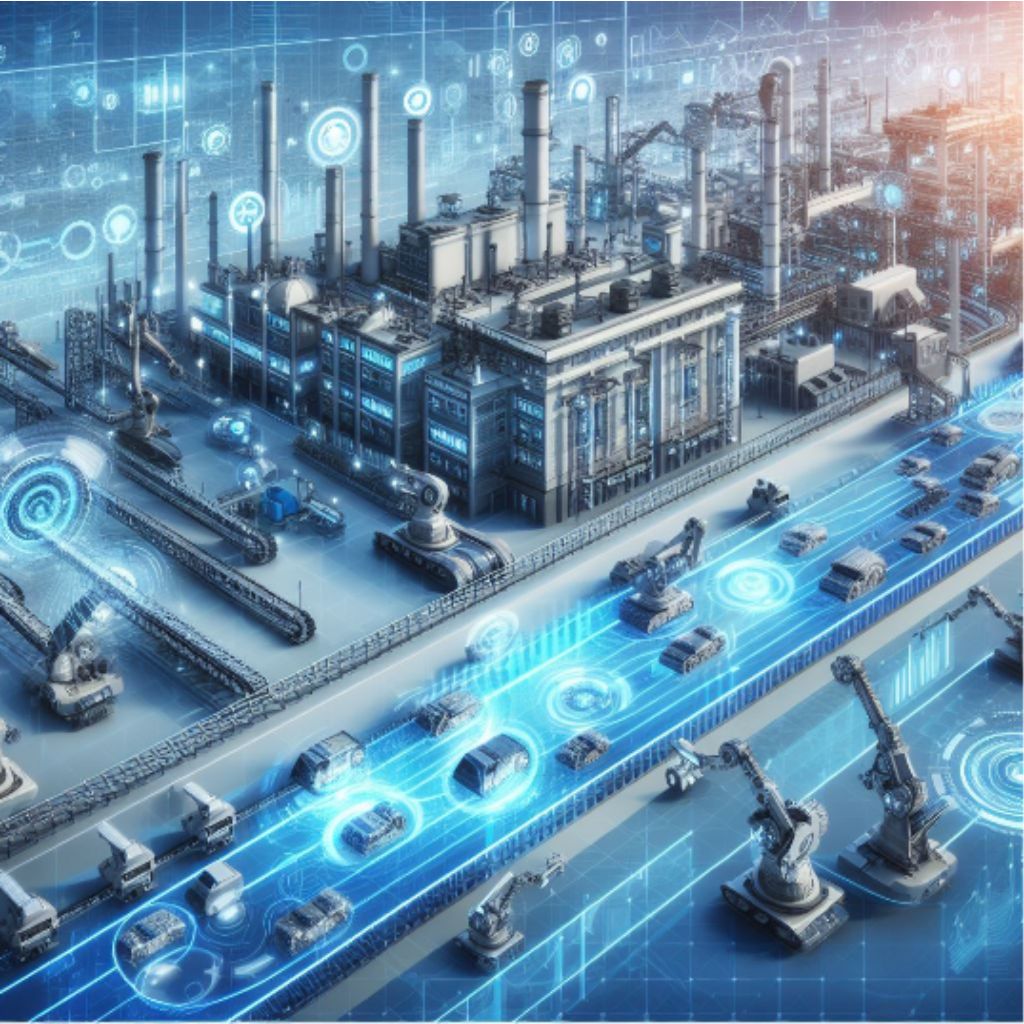

The world of manufacturing is on the brink of a profound transformation. As the Fourth Industrial Revolution takes center stage, we witness the convergence of Artificial Intelligence (AI) and the Internet of Things (IoT) in smart factories. This integration promises to revolutionize the manufacturing landscape, making factories more efficient, agile, and responsive. In this article, we’ll delve into the future of smart factories and explore how Verysell Applied AI Lab can play a pivotal role in this transformation.

The Evolution of Smart Factories

Smart factories, also known as Industry 4.0, represent a paradigm shift in manufacturing. These factories leverage digital technologies to create a more connected and automated environment. The primary components of smart factories are AI and IoT.

AI in Smart Factories

Artificial Intelligence has a profound impact on smart factories in several ways:

- Predictive Maintenance: AI-driven algorithms can predict when machinery is likely to fail, allowing for proactive maintenance, reducing downtime, and optimizing production.

- Quality Control: AI-powered computer vision can inspect products in real-time, ensuring quality and reducing defects.

- Production Optimization: AI can analyze large datasets to optimize production schedules, ensuring maximum efficiency.

- Energy Efficiency: AI can regulate energy usage in real-time, ensuring that factories are operating at their most energy-efficient.

- Supply Chain Management: AI enhances supply chain logistics by predicting demand and optimizing the movement of goods.

IoT in Smart Factories

IoT refers to the network of interconnected devices that gather and exchange data. In smart factories, IoT is essential for the following:

- Sensors and Devices: IoT devices like sensors and RFID tags monitor equipment and collect data, providing insights into real-time operations.

- Connected Equipment: Machines and equipment are equipped with IoT sensors, allowing them to communicate with each other and with central control systems.

- Data Exchange: Data from IoT devices is shared in real-time, enabling immediate responses to changing conditions.

- Inventory Management: IoT-enabled inventory systems automatically track and manage stock levels.

The Future of Smart Factories: AI and IoT Integration

The future of smart factories lies in the seamless integration of AI and IoT. This integration will bring about several key advancements:

- Real-Time Decision-Making

The integration of AI and IoT allows factories to make decisions in real-time. For example, if a sensor detects a drop in machine performance, AI can immediately adjust operations, schedule maintenance, and even order replacement parts, all without human intervention.

- Improved Predictive Analytics

AI, when coupled with IoT data, can provide more accurate predictive analytics. Predictive maintenance becomes more precise, reducing costly downtime, and machine failures become predictable with greater accuracy.

- Enhanced Quality Control

AI and IoT work together to provide unparalleled quality control. Computer vision powered by AI can detect even the smallest defects, ensuring that only top-quality products leave the factory floor.

- Agile Production Lines

Smart factories will have the ability to quickly adapt production lines based on real-time demand. AI will adjust schedules and optimize production to meet changing market needs.

- Energy Efficiency

AI will continuously monitor and adjust energy usage, ensuring that the factory operates at its most energy efficient. IoT sensors will provide data on energy consumption in real-time, enabling rapid adjustments.

How Verysell Applied AI Lab Can Drive the Transformation

Verysell Applied AI Lab is at the forefront of AI and IoT technology, offering solutions and services to support the evolution of smart factories. Here’s how we can be a catalyst for this transformation:

- Custom AI and IoT Solutions

Verysell Applied AI Lab can design AI and IoT solutions tailored to your specific manufacturing needs. Whether you need predictive maintenance systems, quality control applications, or real-time production optimization, our expertise can help you reach your goals.

- Seamless Integration

We have extensive experience in integrating AI and IoT systems into existing manufacturing infrastructure. Our solutions work harmoniously with your current operations, ensuring a smooth transition to the future of manufacturing.

- Data Security and Compliance

We prioritize data security and compliance with manufacturing regulations. Your data will be protected and adhere to industry standards.

The future of smart factories is undoubtedly exciting, with the integration of AI and IoT set to transform manufacturing in unprecedented ways.

Verysell Applied AI Lab, with its cutting-edge solutions and integration expertise, is your trusted partner on this journey. The benefits of real-time decision-making enhanced predictive analytics, improved quality control, agile production lines, and energy efficiency are within your grasp. Embrace the future of manufacturing with AI and IoT and let Verysell Applied AI Lab guide you towards a more efficient, sustainable, and responsive smart factory.